Delivering Automotive Sheet Metal Fabrication Solutions with On-Demand Manufacturing

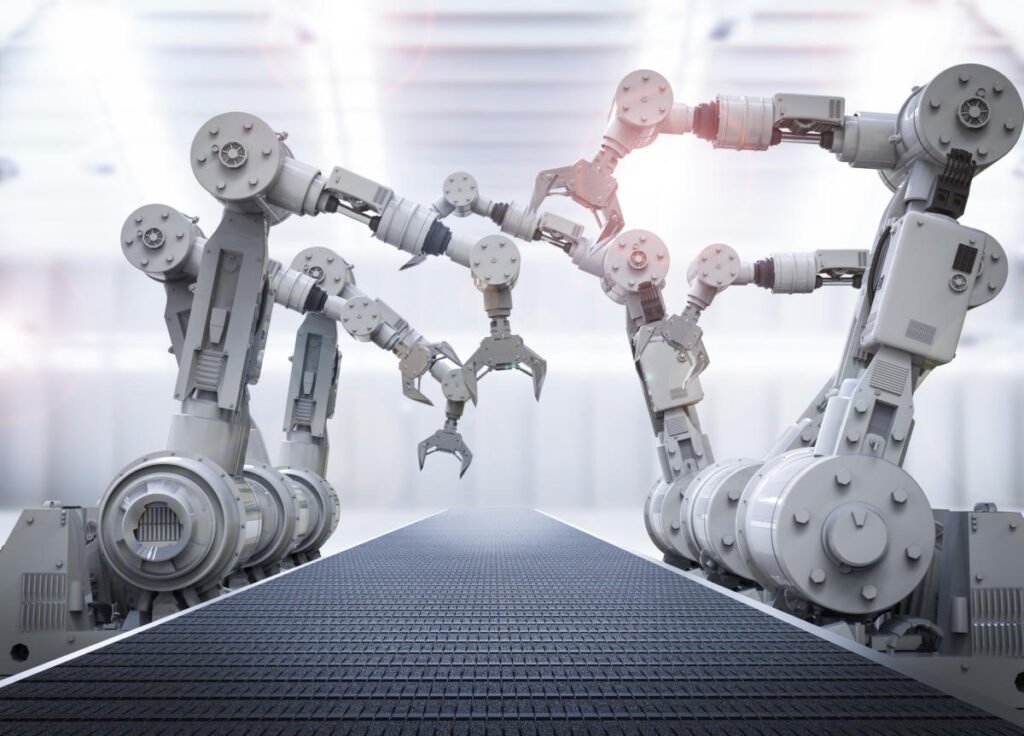

Efficiency, precision, and timeliness are critical factors to success in the automotive industry. However, traditional manufacturing methods often fall short on these aspects, resulting in lengthy lead times, high upfront costs, and excessive waste. The good news is that on-demand manufacturing can be a game-changer in sheet metal fabrication for the automotive sector.

This article explores the concept and process of on-demand manufacturing in sheet metal fabrication for the automotive sector, elucidating its benefits and transformative potential for the larger and advancing automotive field. But first, we will go on to explore the fundamentals.

Understanding On-Demand Manufacturing

On-demand manufacturing refers to a production model wherein parts or components are fabricated only as needed, in response to specific customer orders or demand signals. This method enables greater flexibility, reduced inventory overheads, and minimized wastage.

In the context of sheet metal fabrication for the automotive industry, on-demand manufacturing entails the rapid production of precise, custom-made metal components tailored to the exact specifications of each vehicle model.

Process of On-Demand Sheet Metal Fabrication

The process of fabricating sheet metal is quite exhaustive from designing, and finishing to quality control. Let us find out the steps in detail.

- Digital Design

The process involves meticulous digital design using Computer-Aided Design (CAD) software. Design engineers collaborate closely with automotive manufacturers to conceptualize and refine the geometry, dimensions, and functional attributes of the sheet metal components.

- Prototyping

Upon finalizing the design, rapid prototyping techniques such as 3D printing or CNC machining are employed to fabricate prototype samples. These prototypes undergo rigorous testing and validation to ensure performance, safety, and regulatory standards compliance.

- Material Selection

With the design validated, the appropriate sheet metal material is selected based on strength, durability, weight, and cost. Common materials include steel, aluminum, and advanced alloys, each offering distinct advantages in terms of formability, corrosion resistance, and structural integrity.

- Laser Cutting or Stamping

The chosen sheet metal material is then subjected to precision cutting processes, such as laser cutting or stamping, to shape it into the desired configuration. Advanced laser cutting technologies offer unparalleled accuracy and efficiency, enabling complex designs and tight tolerances to be achieved with minimal material wastage.

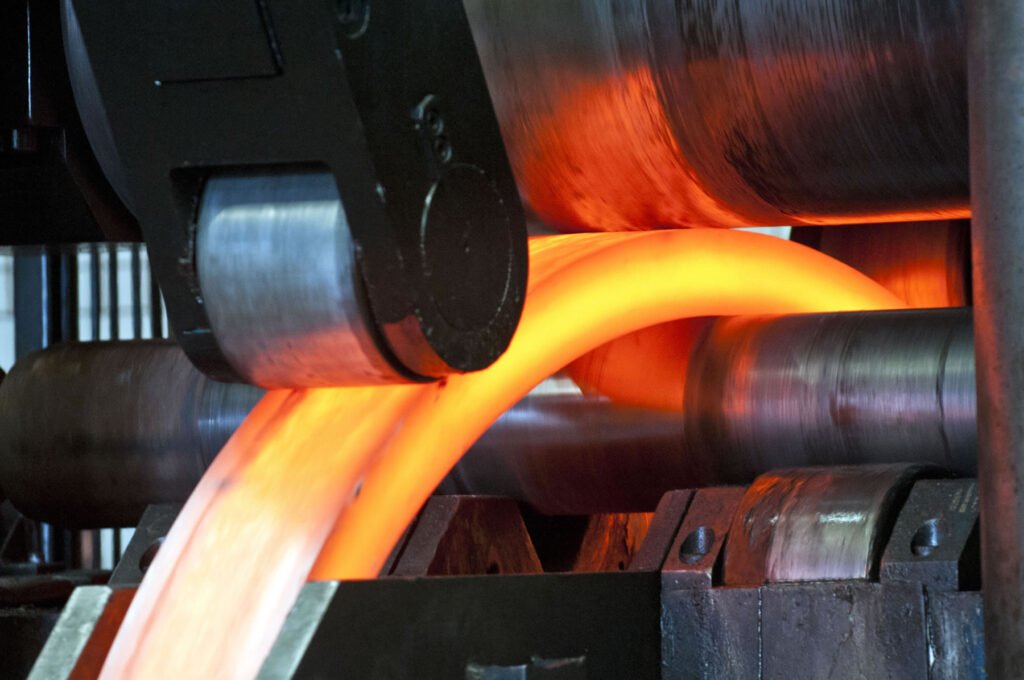

- Bending and Forming

Following cutting, the flat sheet metal blanks undergo bending and forming operations to impart the requisite curvature and contours. Computer Numerical Control (CNC) press brakes are utilized to accurately manipulate the metal, ensuring consistency and uniformity across multiple components.

- Finishing and Surface Treatment

Once formed, the sheet metal components undergo surface finishing treatments such as sanding, deburring, and coating to enhance aesthetics, durability, and corrosion resistance. Powder coating, anodizing, and e-coating are commonly employed to impart a uniform, protective finish.

- Quality Control

Throughout each stage of production, stringent quality control measures are implemented to ascertain dimensional accuracy, material integrity, and surface finish quality. Advanced metrology tools such as Coordinate Measuring Machines (CMMs) are utilized to verify conformance to specifications and detect any deviations or defects.

By carefully selecting the optimal sheet materials for each automotive fabrication application, manufacturers can achieve the desired balance of performance, cost-effectiveness, and sustainability, driving innovation and competitiveness in the dynamic automotive industry landscape.

Benefits of On-Demand Manufacturing in Automotive Sheet Metal Fabrication

Reduced Lead Times

On-demand manufacturing minimizes lead times by eliminating the need for extensive tooling setup and batch production. This enables automotive manufacturers to respond swiftly to fluctuating market demand and rapidly introduce new vehicle models or variants.

Cost Efficiency

By producing sheet metal components on demand, companies can optimize inventory levels, reduce warehousing costs, and mitigate the financial risks associated with excess stockpiles. Moreover, the elimination of tooling expenses and economies of scale allows for cost-effective production of low to medium-volume runs.

Customization and Personalization

On-demand manufacturing facilitates greater customization and personalization, enabling automotive brands to cater to diverse consumer preferences and niche market segments. From bespoke body panels to tailored interior trim elements, the flexibility of on-demand fabrication empowers designers to unleash their creativity and differentiate their offerings.

Sustainability and Waste Reduction

Traditional manufacturing processes often entail substantial material wastage due to overproduction, obsolete inventory, and inefficient production runs. In contrast, on-demand manufacturing minimizes waste generation by producing only what is needed, when it is needed, thereby fostering a more sustainable and environmentally conscious approach to automotive production.

Enhanced Design Freedom

The advanced digital design tools and additive manufacturing technologies provide designers unprecedented freedom to explore complex geometries, lightweight structures, and innovative form factors. On-demand manufacturing enables the realization of these visionary designs without the constraints imposed by conventional manufacturing methods.

On-demand manufacturing represents a transformation in automotive sheet metal fabrication, offering unparalleled agility, efficiency, and customization capabilities. By embracing this transformative approach, big automotive companies and brands can streamline their production processes, accelerate time-to-market, and forge deeper connections with consumers through tailored sustainable, and cutting-edge vehicle designs. As the automotive industry continues to advance, the adoption of on-demand manufacturing will undoubtedly be a cornerstone of innovation and competitiveness in the pursuit of driving the future of mobility.

Contact us today to learn more about on-demand manufacturing and how it can benefit your automotive sheet metal fabrication needs.

Recent Post