The Role of CNC Machining in Manufacturing Robotic Components

In modern manufacturing, Computer Numerical Control (CNC) machining stands out as a core technology, particularly in the production of robotic components. Through precision, efficiency, and versatility, CNC machining plays a central role in shaping the future of robotics.

This article explores the complexities of CNC machining works. its crucial contributions to robotic parts production, and the significance of partnering with reliable vendors like Mechkonnect. Furthermore, we explore how robotics transcends boundaries, revolutionizing various industries with its numerous applications.

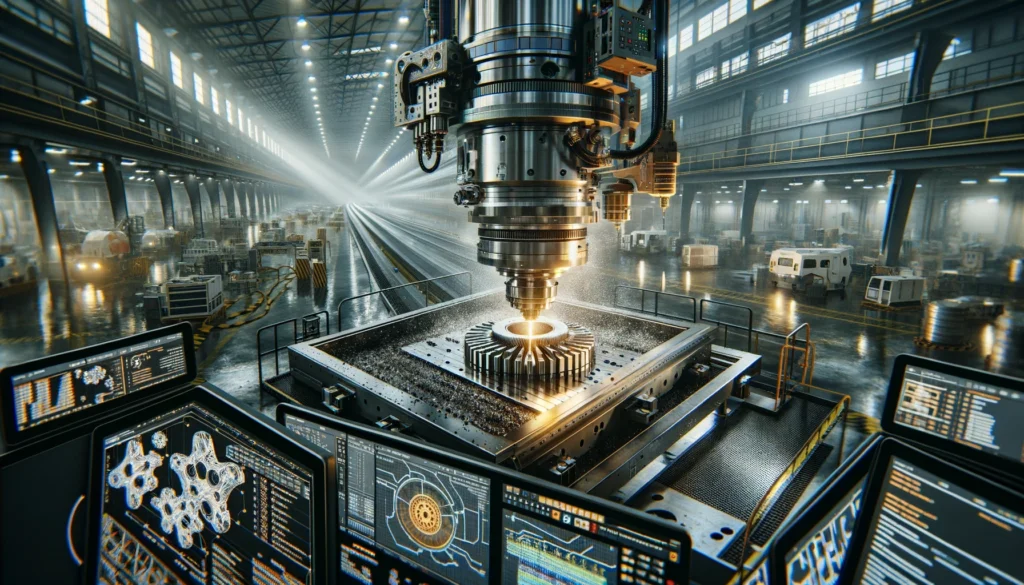

Understanding CNC Machining

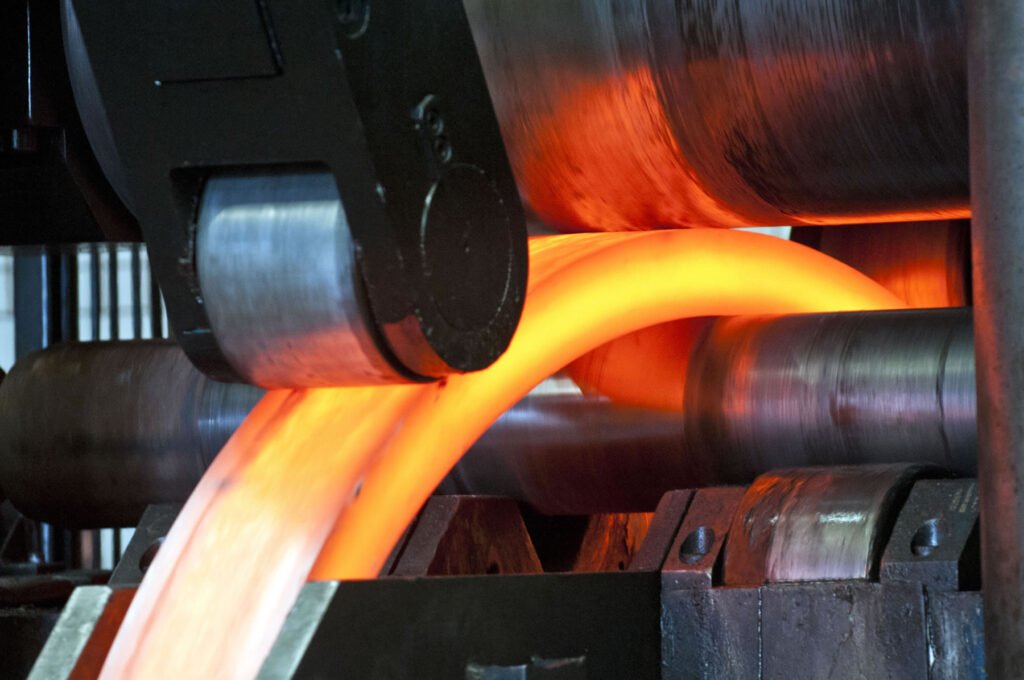

CNC machining represents a manufacturing process where pre-programmed computer software dictates the movement of machinery and tools. It operates on subtractive manufacturing principles, where raw materials like metals, plastics, or composites are carved away to create intricate components with high precision.

The process involves several key components, let’s understand each of them in detail:

- Computer-Aided Design (CAD)

Engineers design the desired component using specialized software, translating conceptual designs into digital models.

- Computer-Aided Manufacturing (CAM)

CAM software converts CAD designs into instructions for CNC machine, specifying toolpaths, cutting depths, and other parameters.

- CNC Machine

This automated equipment executes the programmed instructions, utilizing various cutting tools to shape the raw material according to the specified design.

The Impact of Robotics Across Industries

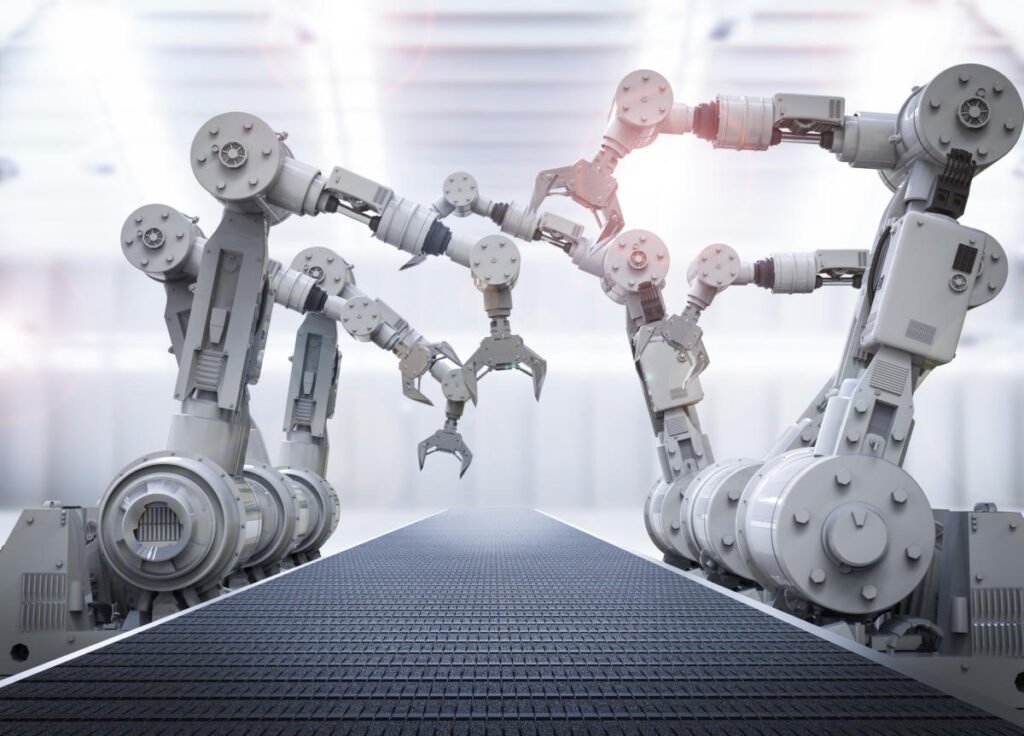

The integration of robotics transcends traditional boundaries, revolutionizing various sectors with its transformative capabilities. Some notable applications include:

Manufacturing

Automation in manufacturing processes streamlines production, enhances efficiency, and ensures consistent quality, driving advancements in the automotive, electronics, and aerospace industries.

Healthcare

Robotics facilitates minimally invasive surgeries, patient care assistance, and drug discovery, revolutionizing healthcare delivery and improving patient outcomes.

Logistics and Warehousing

Autonomous robots optimize warehouse operations, from inventory management to order fulfillment, enabling faster, more efficient supply chain management.

Agriculture

Robotic systems aid in precision farming, crop monitoring, and harvesting, increasing agricultural productivity while minimizing resource consumption and environmental impact.

Contributions of CNC Machining to Robotics Manufacturing

In robotics, precision and reliability are significant. CNC machining offers several advantages that are indispensable in the production of robotic components:

- High Precision

CNC machines can achieve exceptional levels of accuracy, ensuring that critical components like gears, joints, and sensors meet the stringent tolerances required for seamless robotic operation.

- Complex Geometry

Robotics often demand intricate parts with complex shapes and contours. CNC machining excels in producing such components with consistency and repeatability.

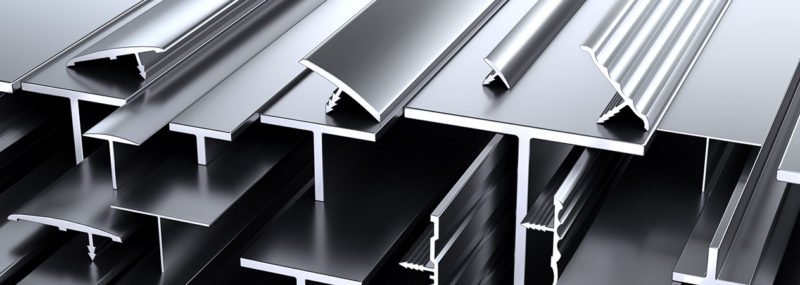

- Material Versatility

From lightweight aluminum alloys to robust stainless steel, CNC machining accommodates a wide range of materials, allowing manufacturers to tailor components to specific robotic applications.

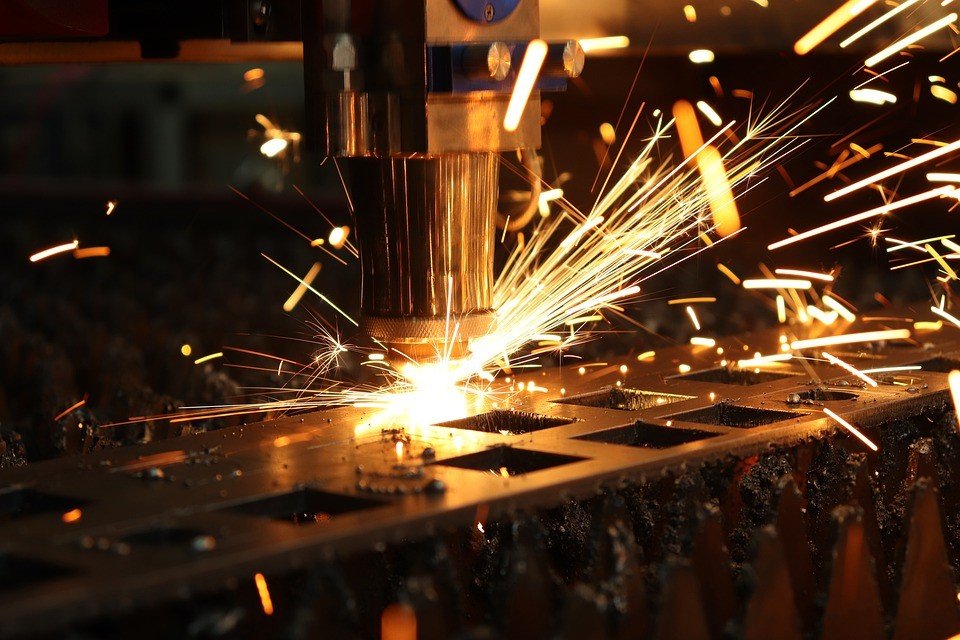

- Efficiency

Automation inherent in CNC machining reduces production time and minimizes errors, leading to faster turnaround and enhanced productivity.

Mechkonnect: Your Reliable Partner in Robotics Components Manufacturing

Mechkonnect emerges as a reliable ally, offering a comprehensive suite of services tailored to the needs of robotic component production. With 10+ years of experience and a dedicated team of professionals and local vendors, Mechkonnect possesses the expertise to tackle the most demanding robotics projects. Equipped with advanced CNC machine working and pioneering technology, Mechkonnect ensures the highest standards of quality and precision in every component produced.

Understanding the unique requirements of robotics, Mechkonnect collaborates closely with clients to deliver bespoke solutions that optimize performance and efficiency. From concept to completion, Mechkonnect upholds uncompromising standards of excellence, fostering long-term partnerships built on trust and reliability.

CNC machining stands as a key player in the manufacturing of robotic components, offering precision, versatility, and efficiency essential for the advancement of robotics. As robotics continues to permeate diverse industries, its transformative impact reshapes the scene of modern technology, promising a future where automation and efficiency converge to redefine human potential.

Are you ready to embrace the advanced future of robotics and automation? Let’s get you started.

Recent Post