An Overview of Contract Manufacturing with Mechkonnect

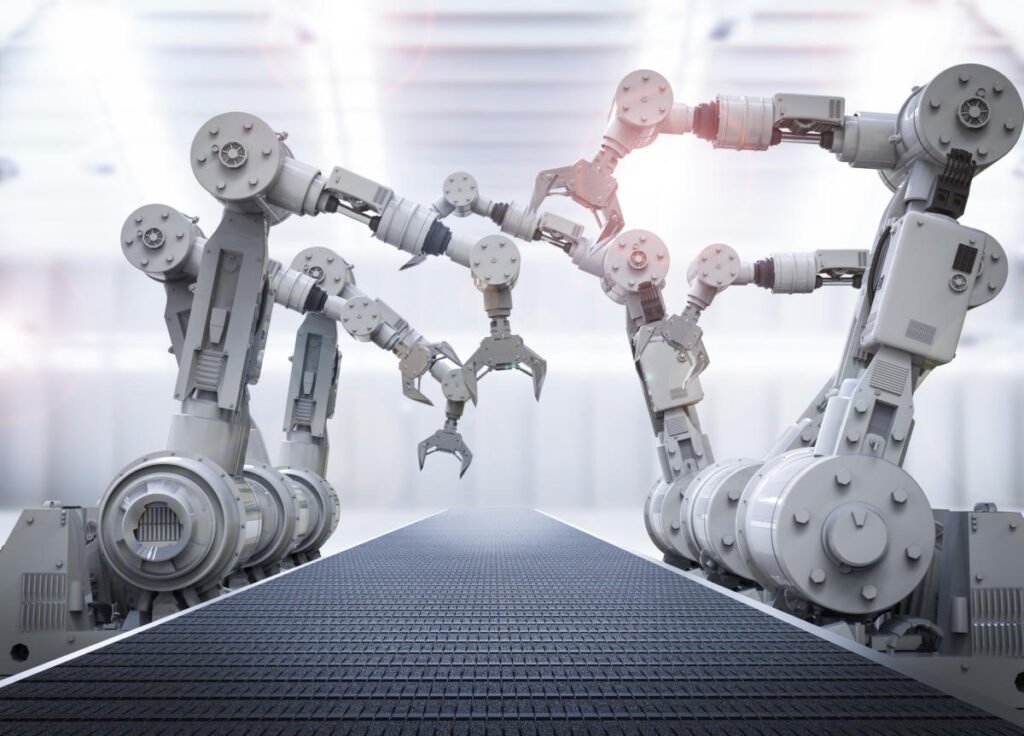

Companies across various industries are increasingly turning to contract manufacturing as a strategic solution to enhance efficiency, reduce costs, and focus on their core competencies.

In this article, we explore the concept of contract manufacturing, its approach, benefits, and how partnering with Mechkonnect can elevate your production processes. Let’s get to the basics first.

In this article, we will explore the various casting processes employed in on-demand manufacturing, from traditional molding to advanced metal casting techniques.

Understanding Contract Manufacturing

Contract manufacturing is a collaborative business arrangement where a company outsources the production of certain components or entire products to a specialized third-party manufacturer. This allows the client company to leverage the expertise and resources of the contract manufacturer, streamlining their operations and fostering innovation.

Approach to Contract Manufacturing

The approach to contract manufacturing involves a meticulous process, starting with the identification of a suitable partner. If you are a client company, say ABC Pvt. Ltd. and you want to get a product manufactured but you don’t have enough machineries, resources or an overall manufacturing unit in place, you will reach out to multiple vendors or contract manufacturers, just like Mechkonnect Industrial Solutions Private Limited, and get quotations from each of them. Whatever suits your budget, you then finalize the one and define the product specifications, quality standards, and delivery timelines, in short, you decide the scope of work and the contract manufacturer takes on the responsibility of production and delivery. It’s that easy and sorted.

Benefits of Contract Manufacturing

Now as you’re aware of the concept of contract manufacturing, let us understand the advantages of it in detail.

- Cost Efficiency

Contract manufacturing eliminates the need for heavy investments in production facilities and equipment. Same way, we at Mechkonnect, with our economies of scale, can produce goods at a lower cost, leading to significant savings for the client.

- Focus on Core Competencies

Companies can concentrate on their core strengths, such as research and development, marketing, and distribution, while a contract manufacturer manages the manufacturing process. This results in increased innovation and market responsiveness.

- Reduced Time-to-Market

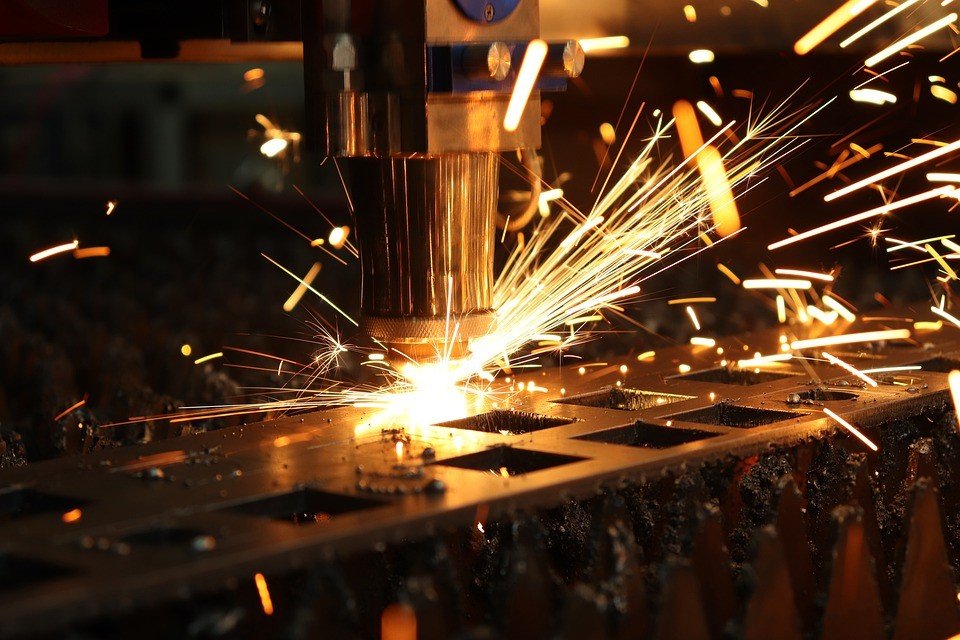

Contract manufacturing accelerates the production timeline. Mechkonnect’s agile processes and advanced technology ensure a faster time-to-market for your products, giving you a competitive edge.

Based on the above advantages of contract manufacturing, now we will explore how it exactly operates:

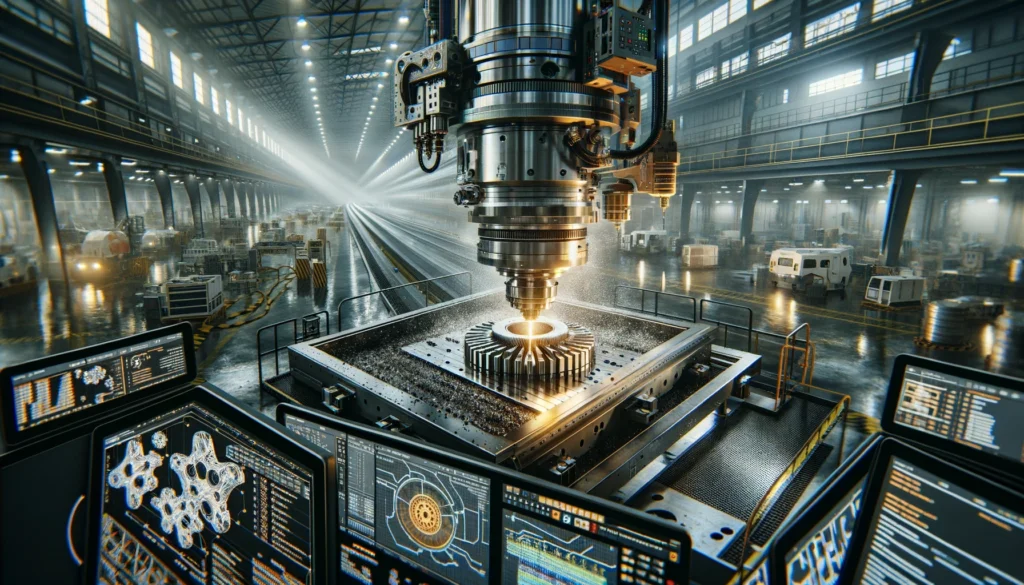

How Contract Manufacturing Works

Contract manufacturing involves a seamless collaboration between the client and the manufacturer. The client provides detailed specifications, including design, materials, and quality standards. Mechkonnect, as a vendor or contract manufacturer with its team of skilled engineers and technicians, translates these specifications into a methodically planned production process. Regular communication and quality checks ensure that the final product meets or exceeds expectations.

Examples of Contract Manufacturing in Various Industries

Electronics

Consumer electronics companies often partner with contract manufacturers to produce components or entire devices. Mechkonnect, with its cutting-edge electronics manufacturing capabilities, ensures precision and reliability.

Automotive

Car manufacturers frequently utilize contract manufacturing for specialized components. Mechkonnect’s expertise in automotive manufacturing guarantees adherence to industry standards and specifications.

Medical Devices

The medical industry benefits from contract manufacturing for the production of medical devices and components. Mechkonnect’s adherence to stringent quality control processes ensures compliance with regulatory standards.

Mechkonnect as Your Contract Manufacturing Partner can be an investment

Mechkonnect has a team of skilled engineers and technicians with a deep understanding of various industries, ensuring that your products are manufactured with precision and excellence. Equipped with advanced technology and modern facilities, We can handle complex manufacturing processes, meeting the highest quality standards. At Mechkonnect, we offer flexible solutions tailored to your specific needs, whether it’s prototyping, small-scale production, or large-scale manufacturing.

Contract manufacturing has emerged as a strategic imperative for companies aiming to enhance efficiency and stay ahead. Mechkonnect, with its commitment to quality, technical prowess, and flexibility, stands out as an ideal partner for companies seeking to optimize their production processes through contract manufacturing.

Embrace the future of manufacturing with Mechkonnect and unlock a new realm of possibilities for your business. Here’s how you can do it!

Recent Post