The Role of Technology in Enabling On-Demand Manufacturing

The manufacturing industry has undergone a significant transformation in recent years, driven by technological advancements and changing consumer demands.On-demand manufacturing, in particular, has emerged as a game-changer, enabling businesses to produce customized products quickly and efficiently. At the heart of this revolution is technology, which plays a vital role in enabling on-demand metal manufacturing.

Enabling Mass Customization

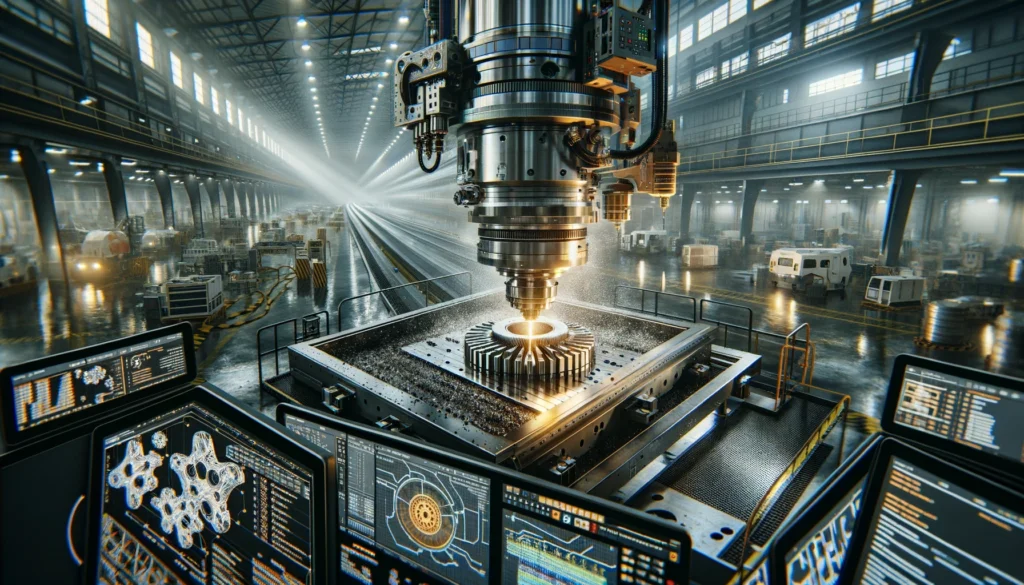

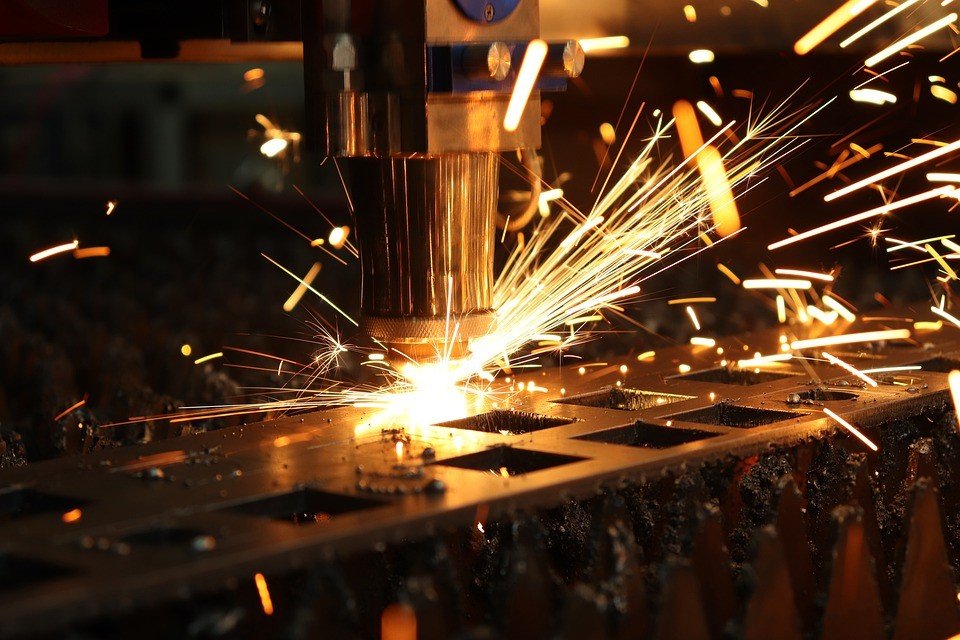

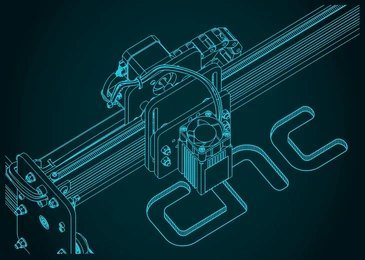

Technology has made it possible to produce customized metal products on a large scale, without compromising on efficiency or cost. Computer-aided design (CAD) software, for instance, allows designers to create complex geometries and customized metal components to meet specific customer requirements. This, combined with advanced manufacturing technologies like 3D printing and CNC machining, enables the rapid production of customized parts and products.

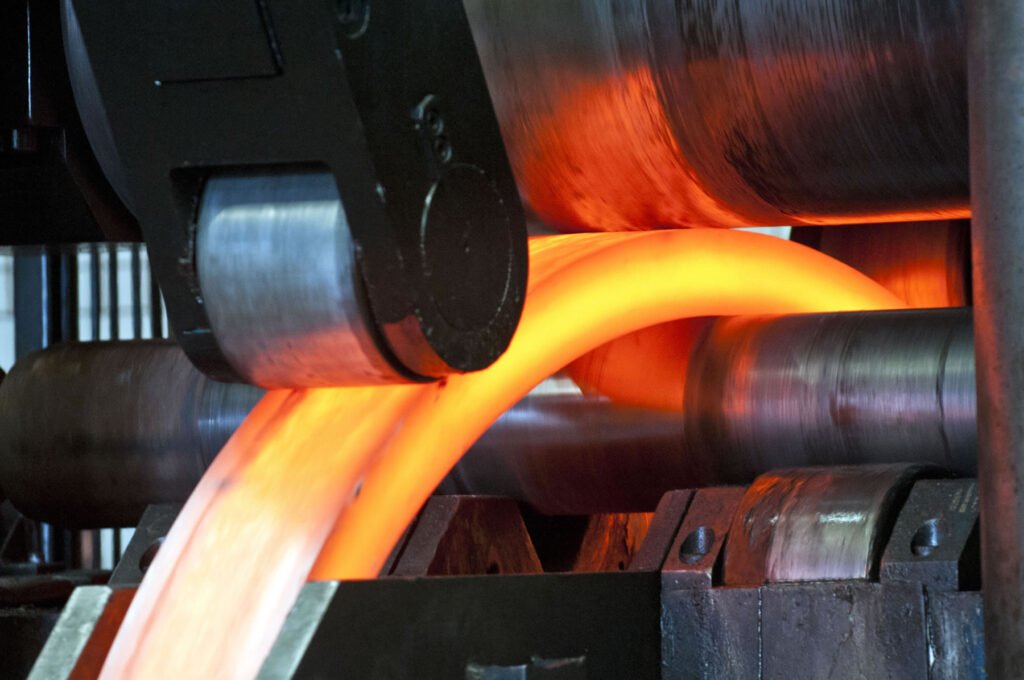

Streamlining Production Processes

Technology has also streamlined metal production processes, enabling businesses to respond quickly to changing customer demands. Enterprise resource planning (ERP) systems, for example, provide real-time visibility into production schedules, inventory levels, and supply chain operations, enabling businesses to make informed decisions and optimize production processes.

Enhancing Supply Chain Agility

On-demand manufacturing requires a high degree of supply chain agility, which technology helps achieve. Digital platforms and marketplaces connect businesses with suppliers and manufacturers, enabling them to source materials and components quickly and efficiently. Blockchain technology, meanwhile, ensures transparency and traceability throughout the supply chain.

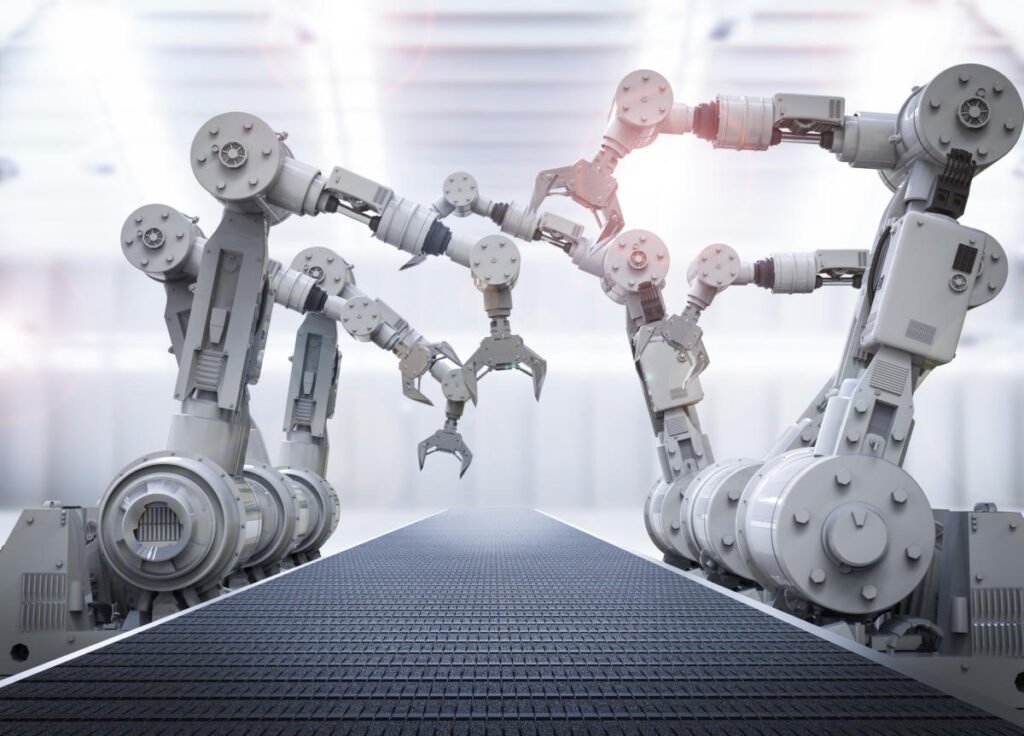

Common Technologies Used in On-Demand Manufacturing

- 3D Printing: Enables the rapid production of complex geometries and customized parts.

- CNC Machining: Allows for precise and efficient machining of parts and products.

- CAD Software: Enables designers to create customized designs and simulate production processes.

- ERP Systems: Provides real-time visibility into production schedules, inventory levels, and supply chain operations.

- Digital Platforms and Marketplaces: Connects businesses with suppliers and manufacturers, enabling efficient sourcing and production.

- Blockchain Technology: Ensures transparency and traceability throughout the supply chain.

- Artificial Intelligence (AI) and Machine Learning (ML): Optimizes production processes, predicts maintenance needs, and enhances product design.

- Internet of Things (IoT): Enables real-time monitoring and control of production processes, ensuring efficiency and quality.

In conclusion, technology plays a vital role in enabling on-demand manufacturing, from design and production to supply chain management. By leveraging these technologies, businesses can respond quickly to changing customer demands, produce customized products efficiently, and stay ahead in a competitive market.

Mechkonnect: Your Partner for On-Demand Manufacturing Solutions

Mechkonnect is a leading provider of on-demand manufacturing solutions, empowering businesses to produce customized products quickly and efficiently. With a robust ecosystem of cutting-edge technologies, including 3D printing, CNC machining, and CAD design, Mechkonnect enables businesses to streamline their production processes, enhance supply chain agility, and deliver high-quality products to customers. Our dedicated team collaborates closely with clients to comprehend their distinct requirements and deliver customized solutions that precisely address their needs. Whether you’re a budding startup or a well-established enterprise, Mechkonnect is the reliable partner you can count on for on-demand manufacturing solutions that fuel innovation, enhance efficiency, and foster sustainable growth.

Recent Post