Robotics in On-Demand Manufacturing: Transforming the Future of Production

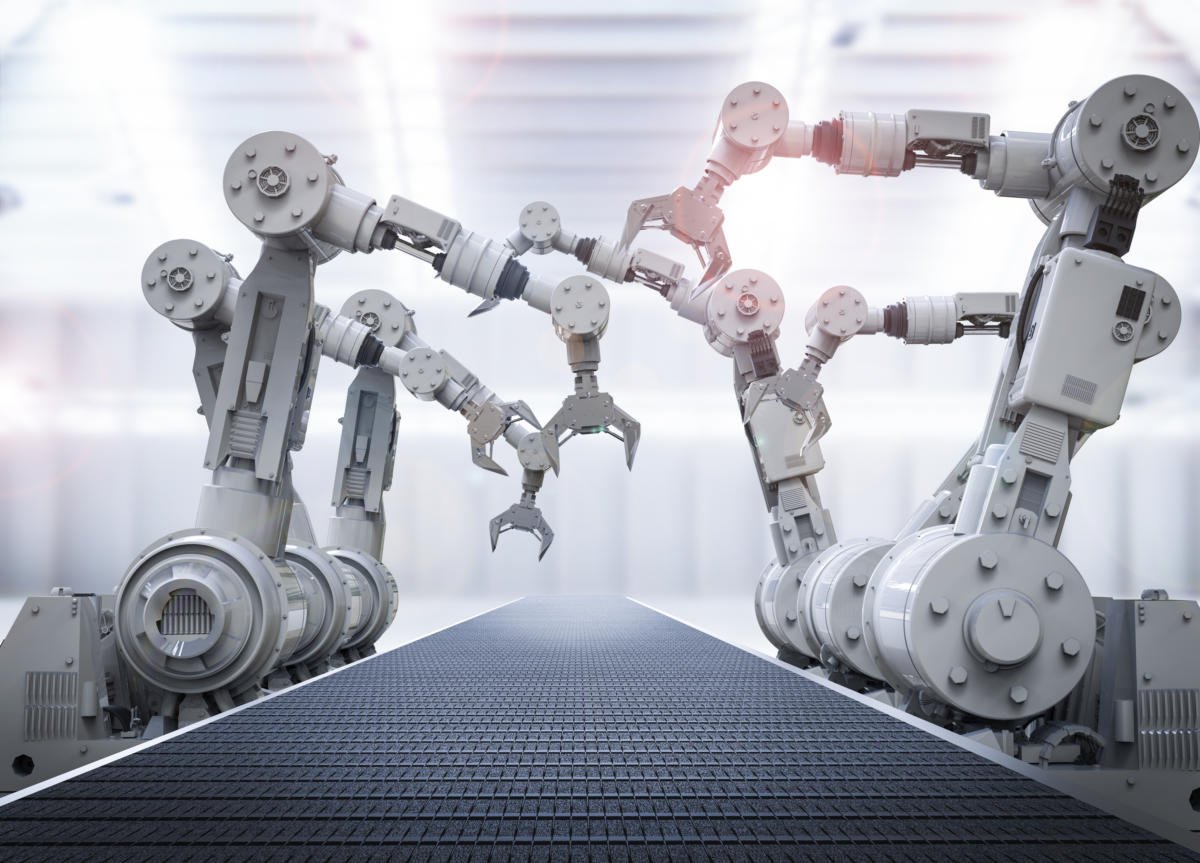

In On-Demand modern manufacturing, where agility, efficiency, and quality are paramount, robotics has emerged as a game-changer. The convergence of automation, artificial intelligence, and robotics is reshaping the way products are made, especially in on-demand manufacturing. Let’s delve into how robotics is revolutionizing this sector and what it means for businesses worldwide.

The Rise of Automation

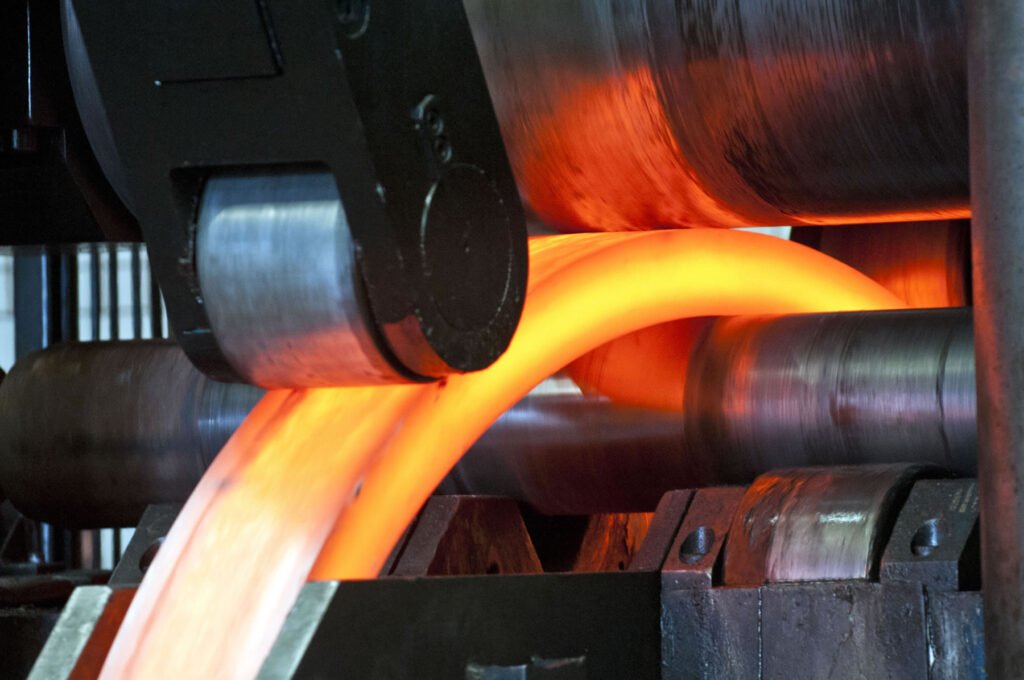

Lights-Out Production

Imagine a factory floor where machines work tirelessly, day and night, without human intervention. This concept, known as “lights-out” production, is becoming increasingly common in modern manufacturing. Industrial robots handle once labour-intensive tasks, freeing human workers from dirty, dull, or dangerous jobs.

The benefits are manifold:

- Robots eliminate errors and reduce variability, leading to consistent product quality.

- Replacing expensive human labour with cost-effective machines reduces manufacturing expenses.

Robots don’t need rest, enabling continuous production without downtime

Falling Robot Prices

Over the past three decades, robot prices have plummeted. The average robot price has halved in real terms, making automation more accessible for businesses. As emerging economies drive robot production to lower-cost regions, we can expect further price reductions.

Accessible Talent

Robotics engineers, once rare specialists, are now widely available. Schools and colleges worldwide offer courses in robotics and automation. Software tools for simulation and offline programming simplify robot design and programming, reducing engineering time and risk.

Ease of Integration

Advancements in computing power and networking technologies have streamlined robot installation and maintenance. Plug-and-play components simplify setup, and sensors monitor themselves, aiding process control and data collection.

Robotics in On-Demand Manufacturing

Consistent Quality

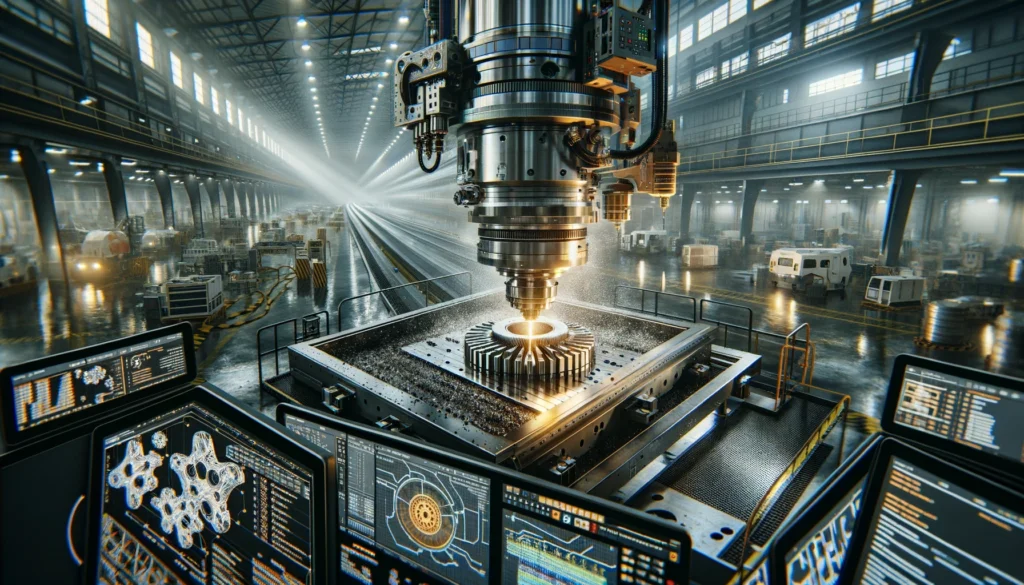

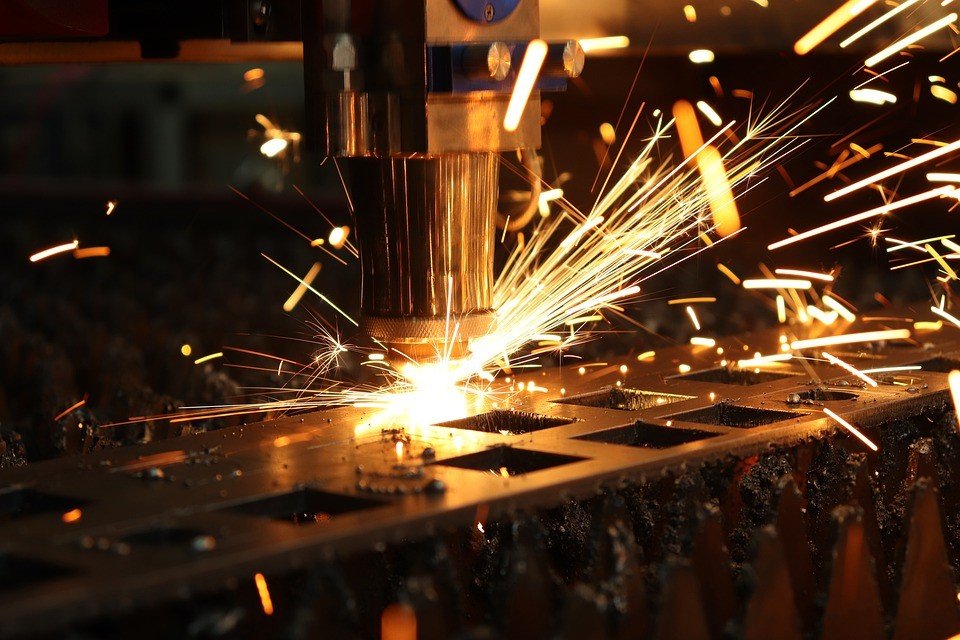

Automated production lines and robots ensure consistent quality. By minimizing human error, manufacturers can deliver reliable products to customers. Whether it’s 3D printing, CNC machining, or assembly, robots maintain precision and repeatability.

Faster Production Times

Optimizing Manufacturing Efficiency with CNC Machines

Recent Post