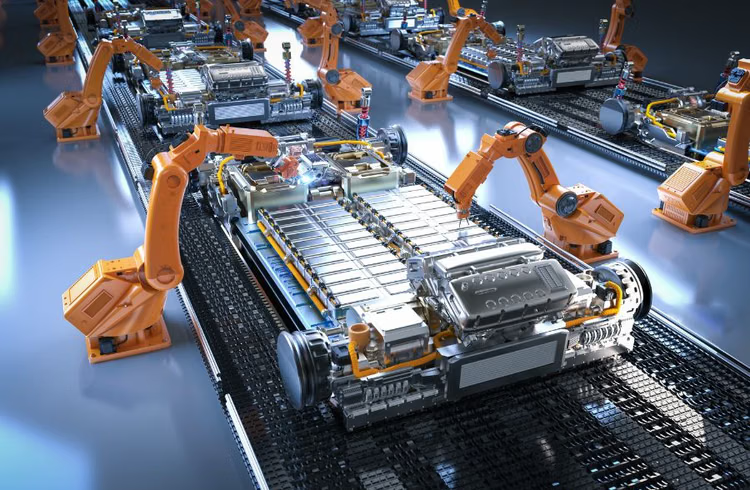

The Scale and Speed of the Electric Vehicle Shift

The growth of electric vehicles is no longer gradual. According to the International Energy Agency, global electric car sales crossed nearly 14 million units in 2023, and early estimates indicate that 2024 saw further growth, pushing EVs close to one-fifth of all new car sales globally. Projections suggest EVs could account for around 30 percent of global vehicle sales by 2030.

This growth is not linear. EV platforms evolve rapidly, with frequent updates to battery architecture, power electronics, thermal systems, and software-driven hardware. Product refresh cycles are significantly shorter than those of internal combustion vehicles, placing pressure on manufacturing systems to keep up.

Why Traditional Manufacturing Models Fall Short for EVs

Conventional automotive manufacturing was designed for stability. Tooling investments were justified over long production runs, and component designs remained largely unchanged for years. Electric vehicles disrupt this logic.

EV components change more frequently, and small design updates can require new tooling. Long procurement cycles increase time to market, while large production batches increase the risk of inventory obsolescence. In a market where speed and flexibility determine competitiveness, these limitations are becoming increasingly visible.

What On-Demand Manufacturing Means in the EV Context

On-demand manufacturing refers to producing parts only when required, using digital design files and flexible production technologies. It shifts manufacturing from forecast-driven production to demand-responsive execution.

Additive manufacturing, or 3D printing, plays a key role in enabling this model. Combined with CNC machining and other flexible processes, it allows manufacturers to create components directly from validated digital designs without extensive tooling.

How On-Demand Manufacturing Supports EV Development

One of the biggest advantages of on-demand manufacturing is the ability to iterate faster. EV development involves constant optimisation of packaging, cooling, and structural components. Additive manufacturing allows engineers to prototype and validate parts such as brackets, housings, ducts, and enclosures in days instead of weeks.

This reduces development risk and accelerates decision-making. Engineering teams can test multiple design variations before committing to high-volume tooling, improving product quality while reducing rework costs.

Material Efficiency and Cost Control in EV Manufacturing

Electric vehicles depend heavily on materials such as aluminium, copper, silver, and advanced polymers. These materials face cost volatility and supply constraints. Efficient use of materials is therefore a commercial necessity.

On-demand manufacturing supports material efficiency by enabling part consolidation, topology optimisation, and precise material placement. By producing only what is needed, manufacturers reduce scrap and avoid excess inventory. This supports both cost control and sustainability goals, which are increasingly important in EV value chains.

From Inventory Heavy to Digitally Driven Supply Chains

Traditional supply chains rely on physical stock. EV manufacturing exposes the risk of this approach when designs change frequently. Unsold or obsolete components quickly become financial liabilities.

Digital inventories offer an alternative. Validated CAD files, approved materials, and qualified processes replace physical stock with digital readiness. Parts can be produced closer to the point of use, reducing lead times and inventory carrying costs. This approach also supports regional manufacturing and faster service part availability.

Use Cases Already Emerging in the EV Industry

On-demand manufacturing is already being used across the EV lifecycle. Common applications include prototyping of battery enclosures and thermal components, production of jigs and fixtures for assembly lines, and low-volume manufacturing of early production parts.

Aftermarket and service components are another growing use case. As EV fleets expand, rapid availability of replacement parts becomes essential to maintain uptime and customer satisfaction.

Why This Matters for Indian EV Manufacturers

India’s EV ecosystem is growing rapidly, supported by policy initiatives and expanding domestic demand. At the same time, India’s additive manufacturing and precision machining capabilities are maturing.

This creates an opportunity to build EV supply chains that are flexible, localised, and resilient. On-demand manufacturing aligns well with Make in India objectives by reducing dependence on long global supply chains while improving responsiveness and cost efficiency.

How Manufacturers Can Start Adopting On-Demand Manufacturing

Adoption does not require a complete overhaul. Manufacturers can begin with pilot projects focused on non-safety-critical parts, tooling, or service components. Clear qualification standards, material validation, and digital design governance are essential.

On-demand manufacturing works best as a hybrid model. High volume, stable components continue to use traditional mass production, while flexible processes absorb variability during development, ramp up, and aftermarket support.

Conclusion: EV Manufacturing Needs Agility, Not Just Scale

Electric vehicles are changing more than how cars are powered. They are redefining how vehicles are designed, produced, and sustained. On-demand manufacturing enables faster iteration, better material efficiency, and reduced inventory risk.

For EV manufacturers, agility is becoming as important as scale. Companies that integrate on-demand manufacturing into their production strategy will be better positioned to compete in a market defined by speed, complexity, and constant change.

Mechkonnect Industrial Solutions Pvt Ltd supports EV manufacturers with on-demand manufacturing capabilities that improve responsiveness, reduce risk, and accelerate time to market. As EV adoption continues to rise, the ability to manufacture on demand will define the next generation of automotive competitiveness.