Choosing the Right Forging Material for the Forging Process in On-Demand Production

When it comes to on-demand production, selecting the right forging material is crucial for ensuring the final product’s quality, performance, and cost-effectiveness. At Mechkonnect Industrial Solutions Pvt. Ltd., we understand the importance of material selection in the forging process and are committed to helping our customers make informed decisions. The forging process plays a key role in determining the strength and durability of the material, making it essential to choose the right material for specific requirements.

With our expertise in the forging process, we guide clients in selecting the ideal material that maximizes performance while reducing costs. Our focus on the forging process ensures that each product meets the highest standards. From initial design to final product, the forging process remains a critical factor in achieving successful on-demand production.

In this article, we will explore the concept of forging, its applications, and the key factors to consider when choosing a forging material for on-demand production and highlight some of the most commonly used materials.

What is Forging?

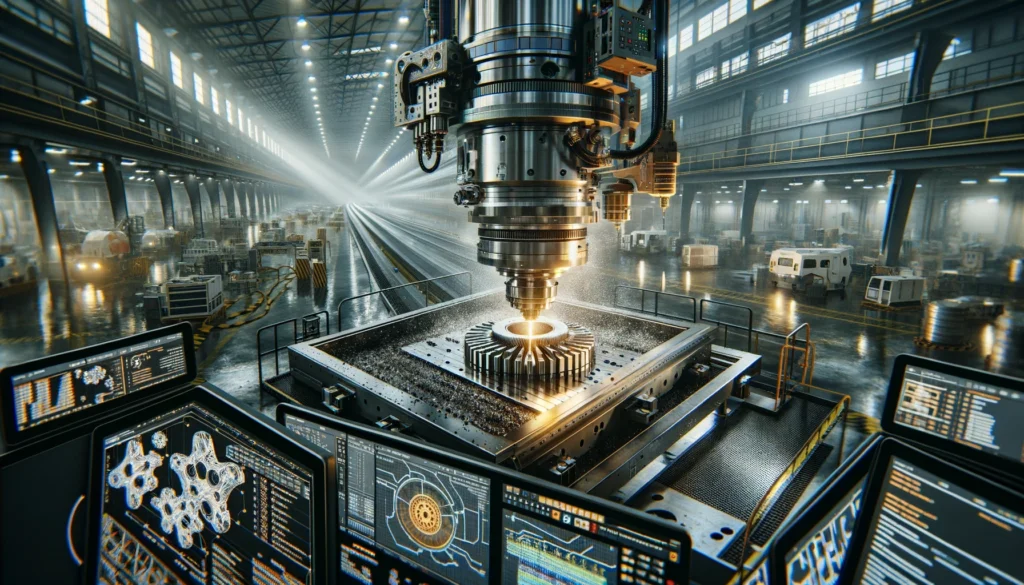

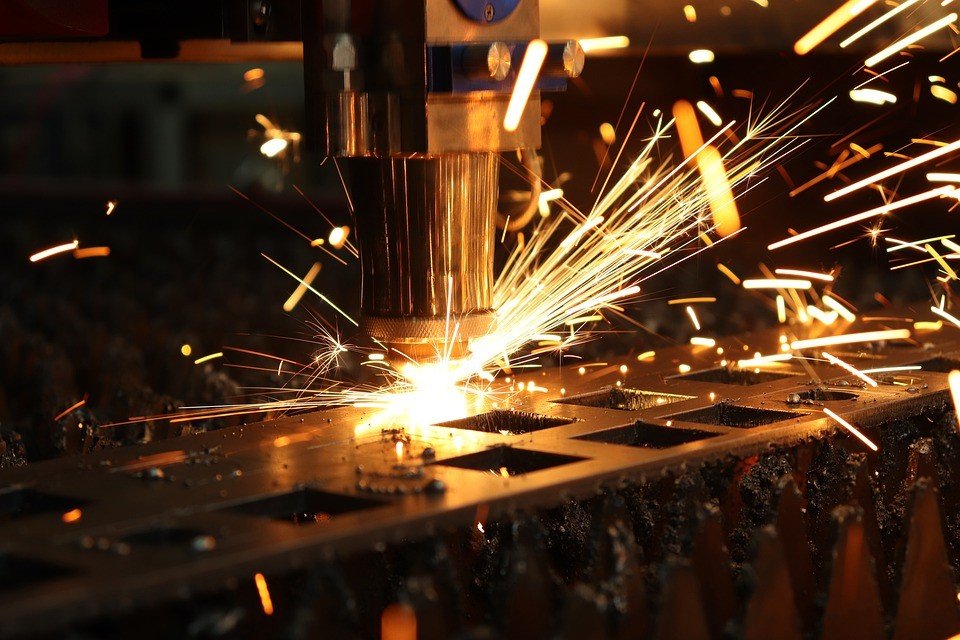

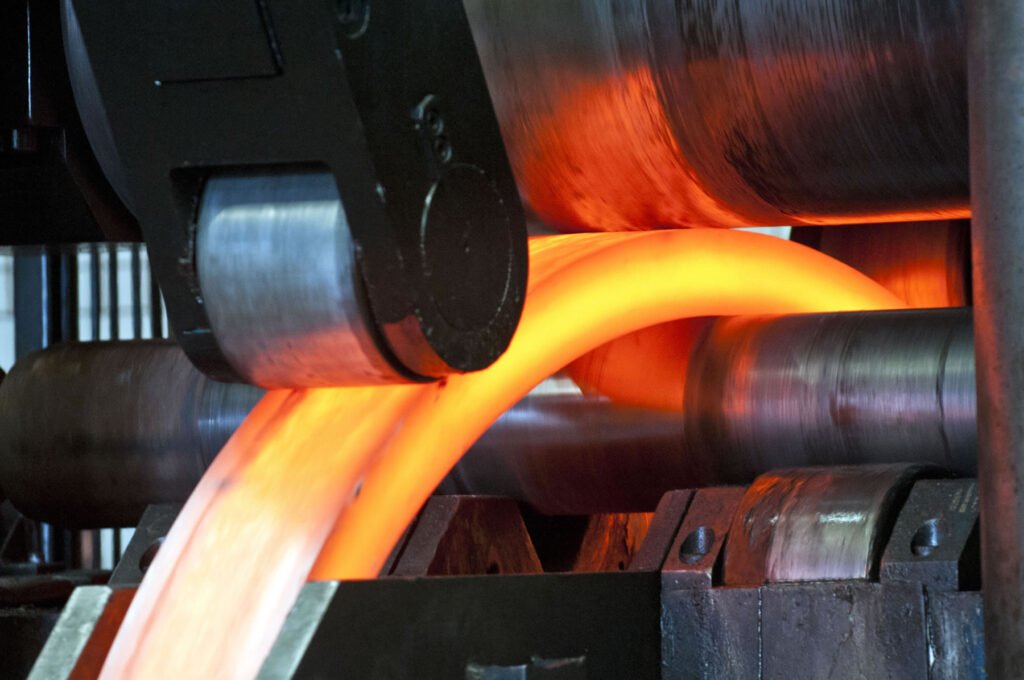

The process of forging involves shaping metal by applying localized compressive forces. It’s an ancient technique that dates back to the early days of metalworking, where blacksmiths would hammer and shape hot metal into various forms.

Why is Forging Needed?

Forging is needed because it allows for the creation of complex shapes and structures that cannot be produced through other manufacturing processes like casting or machining. The forging process also improves the strength and durability of metal by aligning the grain structure and reducing porosity.

Uses and Applications of Forging

- Aerospace Industry: Forging is used to create critical components like engine parts, turbine blades, and landing gear.

- Automotive Industry: Forged parts are used in engines, transmissions, and suspension systems.

- Construction Industry: Forged steel is used in building frames, bridges, and other infrastructure.

- Toolmaking: Forging is used to create tools like hammers, axes, and pliers.

- Medical Equipment: Forged parts are used in medical implants, surgical instruments, and hospital equipment.

- Sports Equipment: Forged metal is used in golf clubs, baseball bats, and other high-performance sports gear.

- Defence Industry: Forging is used to create components for military vehicles, weapons, and armour.

Some common forged products include:

– Fasteners (bolts, nuts, screws)

– Gears and bearings

– Crankshafts and camshafts

– Engine blocks and cylinder heads

– Axles and shafts

– Hand tools and hardware

Factors to Consider

Before selecting a forging material, consider the following factors:

- Application and End-Use: The forging material should suit the intended application and meet the required performance standards.

- Strength and Durability: The material should possess the necessary strength, toughness, and resistance to fatigue and corrosion.

- Machinability and Formability: The item should be easy to machine and form into complex shapes.

- Cost and Availability: The forging component should be cost-effective and readily available to meet production schedules.

- Regulatory Requirements: The material should comply with the relevant industry standards and regulations.

Common Forging Materials

Forging is a versatile manufacturing process that involves shaping metals through heat, pressure, or both. The choice of material is crucial in forging, as it determines the final product’s properties, performance, and applications. Here are some of the most commonly used materials in forging:

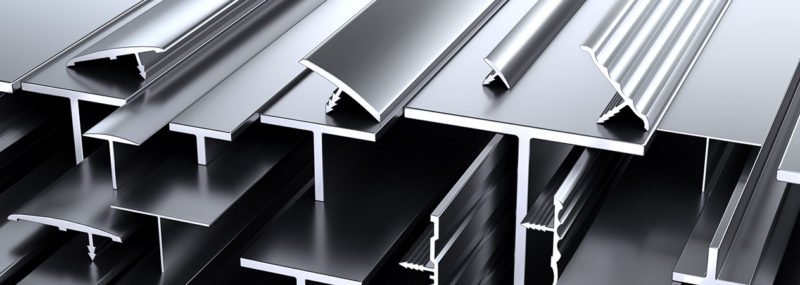

- Carbon Steel: A popular choice for forging due to its high strength, durability, and affordability.

- Alloy Steel: Combines carbon steel with elements like chromium, nickel, or molybdenum for enhanced strength, corrosion resistance, and toughness.

- Stainless Steel: Ideal for applications requiring high corrosion resistance, such as in food processing, pharmaceuticals, or marine environments.

- Aluminium: Lightweight, corrosion-resistant, and easy to forge, making it suitable for aerospace, automotive, and construction industries.

- Copper: Excellent electrical and thermal conductivity, often used in electrical components, heat exchangers, and plumbing fixtures.

- Titanium: High-strength, low-density, and corrosion-resistant, making it perfect for aerospace, medical implants, and high-performance sports equipment.

- Nickel-based Alloys: Inconel, Monel, and Hastelloy are examples of nickel-based alloys, offering exceptional heat resistance, corrosion resistance, and strength.

- Bronze: An alloy of copper and tin, known for its wear resistance, corrosion resistance, and durability, often used in bearings, bushings, and marine hardware.

These materials are widely used in various forging processes, including hot forging, cold forging, and warm forging, to produce a range of components, from simple tools to complex machinery parts.

Material Selection for Forging

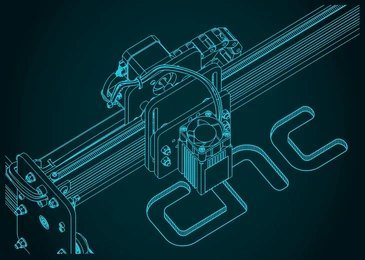

To ensure the right material is chosen for your on-demand manufacturing needs, follow these steps:

- Clearly outline the project’s specifications, including application, performance criteria, and regulatory requirements.

- Our team will help you navigate the material selection process, considering factors like cost, availability, and machinability.

- Conduct thorough testing and validation to ensure the selected material meets the required performance standards.

- Produce prototypes and transition to full-scale production, leveraging Mechkonnect’s expertise in on-demand forging.

Choosing the right forging material is critical for on-demand production success. By considering key factors and selecting from a range of suitable materials, you can ensure your final product meets performance, quality, and cost requirements.

At Mechkonnect Industrial Solutions Pvt. Ltd., our team of experts is dedicated to guiding you through the material selection process and delivering high-quality forged components that meet your specific needs.

Contact us today to discuss your on-demand production requirements.

Recent Post