Custom metal manufacturing is a complex and precise process that involves transforming raw metal materials into tailored metal parts and products that meet specific customer requirements. This intricate process involves several stages, from conceptualisation to final delivery, to ensure that the end product meets the customer’s exact specifications and expectations.

Design and Prototyping: Bringing Ideas to Life

The journey begins with design and prototyping, where customers share their ideas, specifications, and requirements with the manufacturer. Using cutting-edge computer-aided design (CAD) software and 3D modelling tools, manufacturers create detailed designs and prototypes that capture the essence of the customer’s vision. This stage is crucial in ensuring the design is feasible, functional, and meets customer needs.

Material Selection: Choosing the Right Metal for the Job

Next, manufacturers carefully select the appropriate metal material based on the customer’s specifications, considering factors like strength, durability, corrosion resistance, and cost-effectiveness. With a vast array of metals, including aluminium, steel, copper, and more, manufacturers must carefully evaluate each option to ensure the best fit for the project.

Tooling and Machining: Shaping and Forming the Metal

Tooling involves creating custom moulds, dies, or jigs to shape and form the metal into the desired shape. Machining processes like cutting, drilling, milling, and turning are then used to create the final product, with precision and accuracy being paramount.

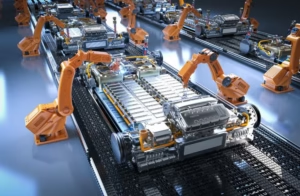

Fabrication of metal and Assembly: Bringing it All Together

Fabrication involves combining multiple metal parts into a single unit, requiring expertise and attention to detail. Assembly involves adding additional components, like hardware or electronics, to create the final product, ensuring seamless integration and functionality.

"Fabrication of metal at MechKonnect covers the entire custom manufacturing process, from design through to delivery, ensuring precision and high-quality results at every stage."

Quality Control and Testing: Ensuring Excellence

Manufacturers conduct rigorous quality control checks and testing to ensure the product meets customer specifications, industry standards, and regulatory requirements. This stage is critical in guaranteeing the product’s performance, safety, and reliability.

Finishing and Coating: Enhancing Appearance and Durability

Finishing processes like grinding, polishing, or sanding enhance the product’s appearance, while coatings like paint, powder, or plating may be applied for corrosion resistance, aesthetic purposes, or functional requirements.

Packaging and Delivery: The Final Touch

Finally, the product is carefully packaged and delivered to the customer, marking the culmination of a successful custom metal manufacturing project.

Mechkonnect: Your Trusted Partner for Custom Metal Manufacturing

For businesses seeking a reliable partner for custom metal manufacturing, Mechkonnect is an ideal choice. With years of experience and expertise in producing high-quality metal parts and products, Mechkonnect ensures that customers receive tailored solutions that meet their exact specifications. From design to delivery, Mechkonnect’s team of experts works closely with customers to ensure seamless communication, timely production, and exceptional quality.

Trust Mechkonnect to bring your custom metal manufacturing projects to life.