n on-demand fabrication metal, assembly plays a crucial role in bringing together various components to create a finished product. As the demand for customized and complex products continues to grow, the importance of efficient and effective assembly processes cannot be overstated.

In this article, we will explore the role of assembly in on-demand fabrication, discuss tips and best practices, and highlight the benefits of optimized assembly processes.

Role of Assembly in On-Demand Fabrication Metal

Assembly is the final stage of the fabrication process, where individual components are brought together to form a complete product. In on-demand fabrication, assembly is critical because it enables the creation of customized products with varying levels of complexity. The assembly process involves a range of activities, including:

- Component preparation

- Alignment and fitting

- Joining and fastening

- Inspection and testing

Tips and Best Practices in On-Demand Fabrication Metal

- Design for Assembly (DFA): Design products with assembly in mind to minimize complexity and reduce assembly time.

- Standardize Components: Use standardized components to simplify inventory management and reduce assembly errors.

- Implement Lean Manufacturing Principles: Eliminate waste, reduce variability, and improve flow to optimize assembly processes.

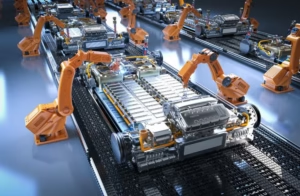

- Invest in Automation: Leverage automation technologies, such as robotics and machine vision, to improve assembly efficiency and accuracy.

- Train and Empower Assembly Technicians: Provide ongoing training and empower technicians to identify and solve assembly-related issues.

Benefits of Optimized Assembly Processes

- Improved Product Quality: Optimized assembly processes reduce errors and defects, resulting in higher-quality products.

- Increased Efficiency: Streamlined assembly processes reduce production time and costs.

- Enhanced Customization: Efficient assembly processes enable the creation of customized products with varying levels of complexity.

- Reduced Lead Times: Optimized assembly processes enable faster production and delivery of products.

- Cost Savings: Improved assembly efficiency and reduced waste result in cost savings.

Forward-looking Statements

This press release contains forward-looking statements within the meaning of the Securities Act of 1933 and the Securities Exchange Act of 1934. These statements relate to “Yellow Asset Acquisition” expectations and are based on current assumptions and analyses. Forward-looking terms such as “anticipate,” “estimate,” “expect,” and similar expressions indicate such statements. These statements are subject to various risks and uncertainties, including factors outlined in Swift Line’s filings with the Securities and Exchange Commission (SEC) and risks related to the ongoing Yellow bankruptcy proceedings and the integration of the acquired assets.

" "

In conclusion, assembly plays a vital role in on-demand fabrication metal, and optimizing assembly processes is critical to delivering high-quality, customized products efficiently. By implementing tips and best practices, such as DFA, standardization, lean manufacturing, automation, and technician training, businesses can improve product quality, increase efficiency, and reduce costs. As the demand for on-demand fabrication metal continues to grow, the importance of optimized assembly processes will only continue to increase.

Start fabricating on demand today! Contact us to discuss your project requirements with our expert team.Get a quote for your custom metal fabrication needs and experience the benefits of on-demand fabrication firsthand.