Forging Through the Ages

The Hammer and Anvil: Time-Tested Techniques

The fundamental tools of forging, the hammer, and the anvil, have been used for centuries. The rhythmic clang of the hammer against hot metal, the precise strikes on the anvil – these are the age-old sounds that resonate with the spirit of craftsmanship. Skilled blacksmiths manipulate the metal, creating intricate designs and ensuring the final product’s strength and durability.

Challenges in Traditional Forging

Enter On-Demand Manufacturing

CNC Forging: Precision in Every Strike

3D Printing: Shaping the Future

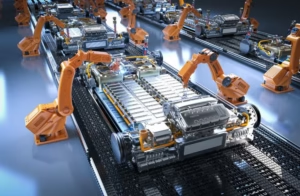

Automated Forging: Efficiency Redefined

Automation has become a key player in on-demand manufacturing. Automated forging processes, guided by advanced algorithms, can produce high volumes of components with minimal human intervention. This not only speeds up production but also enhances consistency and quality control.

Forging, with its ability to produce strong and durable metal components, has a wide range of applications across various industries. The process of forging involves shaping metal through the application of force, typically using hammers, presses, or dies. Here are some key applications of forging:

- Automotive Industry

Forged components are extensively used in the automotive sector for critical parts such as crankshafts, connecting rods, gears, axles, and steering components.

The high strength and impact resistance of forged parts contributes to the safety and performance of vehicles.

- Aerospace Industry

Aerospace applications demand materials with high strength-to-weight ratios, and forging is crucial for producing components like landing gear, turbine discs, and structural elements.

Forged parts in the aerospace industry undergo stringent quality control measures to ensure reliability and safety.

- Oil and Gas Industry

Forged components play a vital role in the oil and gas sector, particularly in drilling and exploration equipment. Parts such as wellhead components, flanges, and valves require the strength and durability provided by forging.

- Construction and Infrastructure

The construction industry relies on forged components for critical structural elements, including bolts, fasteners, gears, and crane hooks. Forging ensures that these components can withstand heavy loads and harsh environmental conditions.

- Power Generation

Forged parts are used in power generation equipment, such as turbine shafts, generator rotors, and steam generator components. The reliability and strength of forged materials are essential for the efficient operation of power plants.

- Military and Defense

Military applications often require components with high tensile strength and durability, making forging a preferred method for producing items like artillery shells, tank components, and aircraft landing gear.

- Medical Equipment

Forging is employed in the production of surgical instruments, prosthetics, and other medical equipment requiring precision and strength. The biocompatibility of certain forged materials makes them suitable for medical applications.

- Mining Industry

Forged components are used in mining equipment, such as drill bits, hammers, and crusher parts. The toughness and wear resistance of forged materials make them well-suited for the demanding conditions of mining operations.

- Railway Industry

Forged components, including wheels, axles, and couplers, are essential for the railway industry. The durability and reliability of forged parts contribute to the safety and efficiency of rail transportation.

- Tool and Die Industry

Forging is used to manufacture tools and dies, including hammers, chisels, and molds. The toughness of forged tools makes them well-suited for applications where impact resistance is crucial.

In summary

The art of forging, with its roots deeply embedded in tradition, has seamlessly integrated with modern innovations in on-demand manufacturing. From the rhythmic strikes of the hammer on the anvil to the precise movements of CNC machines and the layer-by-layer construction of 3D printing, forging has evolved to meet the demands of a rapidly changing industrial landscape. As we continue to push the boundaries of what is possible, the synthesis of traditional craftsmanship and cutting-edge technology ensures that the art of forging remains a vibrant and indispensable part of manufacturing.