In the technology and innovational dynamics, smart materials have become a path breaker. These

materials, also known as intelligent materials, possess the remarkable ability to respond to

environmental stimuli, making them ideal for a wide range of applications.

In this article, we delve into the fascinating world of smart materials, exploring their types,

applications, and the transformative impact they have on on-demand products.

On-Demand Manufacturing and Smart Materials

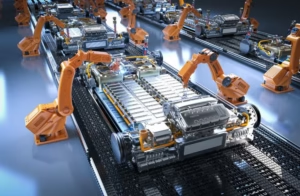

Smart materials, with their ability to adapt and respond to environmental changes, are

revolutionizing the landscape of manufacturing. These intelligent materials enhance efficiency,

customization, and sustainability across various industries.

Let’s explore some applications of smart materials in on-demand manufacturing:

1. Additive Manufacturing (3D Printing)

Additive manufacturing (AM), commonly known as 3D printing, has transformed traditional

manufacturing processes. It allows for rapid prototyping, customized designs, and intricate

geometries. Here are some key applications:

a. Customized Components:

AM enables the production of fully customized parts, tailored to specific requirements. Whether it’s

a complex aerospace component or a medical implant, smart materials enhance precision and

functionality.

b. Topological Optimization :

Smart materials play a crucial role in optimizing part designs. By using lightweight, high-strength

materials, AM ensures efficient use of resources while maintaining structural integrity.

c. Bioprinting :

In the medical field, bioprinting uses smart materials to create synthetic organs, tissue scaffolds, and

surgical tools. It’s a groundbreaking application that holds immense promise for personalized

healthcare.

2. Cloud Computing and Data Analytics

Smart factories leverage cloud computing to enhance efficiency and flexibility. Here’s how:

a. Real-Time Monitoring :

Cloud-based platforms allow real-time monitoring of machine performance, predictive maintenance,

and quality control. Smart materials contribute to accurate data collection and analysis.

b. Resource Optimization :

By using cloud services on demand, manufacturers can optimize resource allocation, reduce waste,

and improve overall productivity.

3. Machine Learning and Predictive Maintenance

Machine learning (ML) algorithms analyze data from sensors and smart devices. Smart materials

embedded with sensors provide real-time data on equipment health. ML algorithms predict

maintenance needs, minimizing downtime and maximizing production efficiency.

Smart materials are reshaping the way we design, manufacture, and interact with products. As

technology advances, integrating intelligence into on-demand products becomes not just a possibility

but a necessity. Whether it’s transportation, robotics, or manufacturing, smart materials are the key

to a smarter, more efficient future.

How MechKonnect Can Help

MechKonnect Industrial Solutions Pvt. Ltd, a trusted player in the industry, offers personalized

manufacturing services. Their capabilities include:

Casting: Precision metal components for diverse needs

Fabrication: Customized structures and assemblies

Machining: Finely produced components meeting industry standards

Forging: Durable components for demanding applications

3D Printing: Rapid prototyping and intricate part production

MechKonnect simplifies obtaining customized parts by connecting industries with a network of

verified vendors. Their commitment to quality, flexibility in payment options, and data security make

them an ideal partner for businesses seeking excellence in manufacturing.

Discover how smart materials and 3D printing are transforming on-demand product manufacturing. At Mechkonnect, we combine intelligent materials with 3D printing technologies to enhance product performance, reduce costs, and improve sustainability. By leveraging 3D printing alongside smart materials, we offer innovative solutions for custom, high-quality products with improved durability and efficiency. This integration allows for more precise and flexible manufacturing processes, opening up new possibilities for industries seeking advanced, on-demand production capabilities.

Need a custom part on- demand ? We’re here to make it happen!