Applications of On-Demand Manufacturing in India

- Prototyping and Rapid Iteration

On-demand manufacturing provides a quick and cost-effective solution for prototyping and rapid iteration. This is especially crucial in industries such as product design, where quick adjustments and modifications are necessary. By leveraging on-demand manufacturing, Indian businesses can accelerate their product development cycle and bring ideas to market faster.

- Customization and Personalization

The ability to customize products according to individual customer preferences is a significant advantage of on-demand manufacturing. In industries like fashion, footwear, and consumer electronics, this enables businesses to offer personalized products to consumers without the need to maintain extensive inventories. Indian manufacturers can tap into the growing demand for customized products and enhance customer satisfaction.

- Small-Batch Production

Traditional mass production often requires large minimum order quantities, making it challenging for small businesses to enter the market. On-demand manufacturing allows for small-batch production, enabling startups and SMEs in India to produce goods in limited quantities without incurring excessive costs. This fosters entrepreneurship and innovation across various sectors.

- Reducing Inventory Costs

On-demand manufacturing minimizes the need for maintaining large inventories. This is particularly advantageous in industries where demand fluctuates or where products have a short lifecycle. By producing items as needed, businesses can avoid overstock situations, reduce warehousing costs, and improve overall supply chain efficiency.

- Spare Parts Production

On-demand manufacturing is a boon for industries that deal with spare parts and components. Instead of stockpiling a vast array of spare parts, manufacturers can produce them on demand, saving on storage costs and reducing the risk of obsolete inventory. This is especially beneficial for industries such as automotive and aerospace in India.

Advantages of On-Demand Manufacturing in India

- Cost Efficiency

On-demand manufacturing eliminates the need for mass production, reducing the costs associated with excess inventory, storage, and waste. Businesses in India can optimize their production processes, saving money and allocating resources more efficiently.

- Flexibility and Agility

The dynamic nature of on-demand manufacturing allows for quick adjustments to production schedules and product designs. This flexibility is crucial in adapting to market trends, responding to customer feedback, and staying ahead of the competition.

- Reduced Lead Times

On-demand manufacturing significantly reduces lead times compared to traditional manufacturing models. This is particularly advantageous for industries where time-to-market is critical. Indian businesses can capitalize on faster production cycles to meet consumer demands more promptly.

- Environmental Sustainability

By minimizing excess production and waste, on-demand manufacturing contributes to environmental sustainability. With a growing awareness of environmental issues, Indian industries can embrace this eco-friendly approach to manufacturing, aligning with global sustainability goals.

- Empowering Small Businesses

On-demand manufacturing levels the playing field for small businesses in India, enabling them to compete with larger counterparts. The lower entry barriers and reduced financial risks associated with small-batch production foster innovation and entrepreneurship.

Challenges of On-Demand Manufacturing in India Future Trends in On-Demand Manufacturing

As on-demand manufacturing continues to gain prominence in the global industrial landscape, several exciting trends are emerging that could shape the future of this dynamic production model. In India, as businesses increasingly embrace the concept of on-demand manufacturing, staying abreast of these trends will be crucial for maintaining a competitive edge and maximizing the benefits of this innovative approach.

Advancements in Additive Manufacturing (3D Printing)

Additive manufacturing, particularly 3D printing, is poised to play a central role in the future of on-demand manufacturing. Ongoing advancements in 3D printing technology, including the use of new materials and improved printing speeds, enhance the capabilities of on-demand production, enabling more complex and customized designs.

IoT Integration for Smart Manufacturing

The Internet of Things (IoT) revolutionizes on-demand manufacturing by facilitating real-time monitoring and control of production processes. Smart sensors embedded in machinery and products provide valuable data, optimizing production efficiency, reducing downtime, and enabling predictive maintenance strategies for manufacturers in India.

Blockchain for Enhanced Transparency and Security

Blockchain technology is gaining traction as a solution to enhance transparency and security in supply chains. In on-demand manufacturing, blockchain is utilized to track the production journey, ensuring authenticity, preventing counterfeiting, and providing a transparent and immutable record of every step in the manufacturing process.

Artificial Intelligence for Predictive Analytics

The integration of artificial intelligence (AI) and machine learning into on-demand manufacturing processes enables predictive analytics. Manufacturers in India can leverage AI algorithms to forecast demand more accurately, optimize production schedules, and proactively address potential issues in the production cycle.

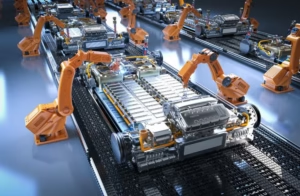

Robotics and Automation for Increased Efficiency

Robotics and automation become more integral to on-demand manufacturing, enhancing production speed, precision, and flexibility. Collaborative robots, known as cobots play a crucial role in automating repetitive tasks, freeing up human resources for more complex and creative aspects of production.

On-Demand Bioprinting for Healthcare Applications

In the healthcare sector, on-demand bioprinting is a trend with the potential to revolutionize the production of personalized medical devices and even organs. As technology progresses, this trend may contribute to significant advancements in the field of regenerative medicine in India and globally.

Cloud-Based Manufacturing Platforms

Cloud-based platforms are transforming the way manufacturers manage and access data. In on-demand manufacturing, cloud-based systems facilitate collaboration, seamless file sharing, and real-time communication. This trend is particularly advantageous for distributed teams and businesses operating in different regions of India.

Circular Economy Practices

Sustainability is becoming a key consideration in manufacturing. On-demand manufacturing can align with circular economy principles by reducing waste, encouraging product refurbishment, and promoting the use of recyclable materials. Manufacturers in India are likely to explore more eco-friendly practices to meet evolving consumer expectations.

Mass Customization with AI-Driven Design

Artificial intelligence will play a crucial role in enabling mass customization in on-demand manufacturing. AI-driven design tools can generate and optimize product designs based on individual customer preferences, allowing businesses in India to offer a wide range of customized products efficiently.

Decentralized Manufacturing Networks

The rise of decentralized manufacturing networks, enabled by digital technologies, allows businesses to tap into a global network of suppliers and manufacturers. This trend facilitates a more agile and responsive production model, providing Indian manufacturers with access to a diverse range of resources and capabilities.

The future of on-demand manufacturing in India is set to be shaped by a convergence of technological advancements, sustainability considerations, and a shift towards more agile and data-driven production processes. Staying attuned to these trends will be crucial for businesses seeking to harness the full potential of on-demand manufacturing and remain competitive in an evolving industrial landscape.

On-demand manufacturing is ushering in a new era of production in India, offering a plethora of benefits across diverse industries. From accelerating product development to fostering customization and sustainability, the applications and advantages of on-demand manufacturing are reshaping the manufacturing landscape in the country. As Indian businesses continue to embrace this innovative approach, the potential for growth and competitiveness in the global market becomes increasingly promising.

While on-demand manufacturing presents numerous advantages, it is essential to acknowledge the challenges that businesses may face when implementing this innovative production model in India.

- Technological Barriers

One of the primary challenges is the need for advanced technologies and digital infrastructure to support on-demand manufacturing. Small and medium-sized enterprises (SMEs) in India may struggle to adopt the required technological solutions, hindering their ability to fully embrace this modern manufacturing approach.

- Skilled Workforce

On-demand manufacturing relies heavily on skilled personnel proficient in digital technologies, automation, and additive manufacturing processes. The shortage of a skilled workforce in India, particularly in emerging fields like 3D printing and advanced robotics, poses a significant challenge for companies aiming to transition to on-demand manufacturing.

- Supply Chain Complexity

The shift to on-demand manufacturing can introduce complexities into the supply chain. Coordinating with suppliers, managing just-in-time inventory, and ensuring seamless logistics require a robust and well-integrated system. For many businesses in India, streamlining the supply chain for on-demand production may be a daunting task.

- Quality Control and Standardization

Maintaining consistent product quality becomes a challenge when moving away from traditional mass production. On-demand manufacturing involves frequent changes in production parameters, making it crucial to establish robust quality control processes. Ensuring standardization across varying production runs is a significant hurdle that businesses in India must overcome.

- Regulatory Compliance

The regulatory landscape in India may not be fully adapted to the nuances of on-demand manufacturing. Navigating regulations related to intellectual property, product safety, and industry-specific standards can be challenging. A proactive approach from regulatory bodies is required to create an environment conducive to the growth of on-demand manufacturing.

- Initial Investment and Cost Considerations

While on-demand manufacturing can be cost-efficient in the long run, the initial investment in technology, staff training, and infrastructure upgrades can be substantial. This financial barrier may be a deterrent for many businesses in India, particularly smaller enterprises with limited resources.

- Cultural Shift and Resistance to Change

Shifting from traditional manufacturing methods to on-demand processes requires a cultural and organizational shift. Resistance to change, both from employees and management, can impede the smooth adoption of on-demand manufacturing practices in India. A comprehensive change management strategy is crucial to overcome this challenge.

- Intellectual Property Concerns

The digital nature of on-demand manufacturing raises concerns about intellectual property (IP) protection. Ensuring the security of digital design files and preventing unauthorized replication of products are critical considerations. The legal framework in India needs to evolve to address these concerns and provide adequate protection for intellectual property.

- Economic and Market Volatility

On-demand manufacturing relies on accurate demand forecasting to optimize production. However, economic uncertainties and market volatility can complicate this process. Businesses in India may find it challenging to predict fluctuations in demand accurately, affecting production planning and efficiency.

While on-demand manufacturing offers a promising path for Indian industries, addressing these challenges is imperative for a successful transition. Collaborative efforts between government bodies, industry stakeholders, and technology providers are essential to create an ecosystem that supports and accelerates the adoption of on-demand manufacturing in India.

In recent years, on-demand manufacturing has emerged as a game-changer in the industrial landscape, offering a dynamic and flexible approach to production. This manufacturing model is particularly gaining traction in India, a country known for its diverse industries and growing economy. In this article, we will delve into the applications and advantages of on-demand manufacturing in India, shedding light on how this innovative approach is reshaping the traditional production paradigm.