At the heart of this transformation lies the Make in India initiative, which has turned train manufacturing into a hub of innovation, advanced engineering, and domestic value creation. This is not just about improving travel; it is about redefining industrial capabilities, fostering skilled employment, and positioning India as a global manufacturing leader in rail technology.

From Legacy to Leap: The Journey of India’s Rail Manufacturing

For decades, Indian train manufacturing primarily revolved around producing conventional passenger and freight coaches. Most advanced train technologies were imported, and indigenous innovation was minimal. The shift began in the last decade with government reforms, public-private partnerships (PPP), and the launch of Make in India in 2014.

The result? A leap from dependence on foreign designs to homegrown high-speed trains like Vande Bharat Express, metro coaches made entirely in India, and modern freight locomotives capable of hauling heavier loads at higher speeds.

Make in India: The Catalyst for Modern Rail Innovation

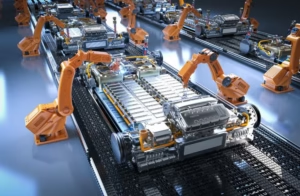

The Make in India program’s railway focus includes:

- Indigenous manufacturing of high-speed trains, metro coaches, and electric locomotives.

- Upgradation of manufacturing units like the Integral Coach Factory (ICF), Modern Coach Factory (MCF), and Rail Coach Factory (RCF) with world-class production lines.

- Local sourcing mandates that require components and systems to be sourced from Indian manufacturers, boosting ancillary industries.

- Technology transfer agreements that encourage Indian companies to collaborate with global rail giants for joint production.

These initiatives are not just modernizing trains; they are building domestic manufacturing capacity that can compete on a global scale.

The Rise of Indigenous High-Speed Trains

The Vande Bharat Express is the crown jewel of India’s modern railway evolution. Designed and manufactured in India at the ICF, it represents a paradigm shift in passenger train technology:

- Speed: Capable of running at 180 km/h.

- Energy Efficiency: Reduced energy consumption through regenerative braking.

- Passenger Comfort: Onboard Wi-Fi, automatic doors, GPS-based passenger information systems, and aircraft-style seating.

This is just the beginning. Plans for Vande Bharat 2.0 and 3.0 promise faster speeds, improved aerodynamics, and smart maintenance systems powered by AI and IoT.

Metro Manufacturing: Urban Transit’s Indian Story

India’s rapid urbanization has driven massive metro rail projects across cities like Delhi, Mumbai, Pune, Nagpur, and Bengaluru. Most metro coaches are now manufactured domestically by companies such as BEML, Titagarh Rail Systems, and Alstom India, under Make in India requirements.

Benefits of local metro coach production:

- Cost Savings through reduced imports.

- Faster Project Timelines with local supply chains.

- Skilled Employment in manufacturing clusters.

- Technology Spillover into other sectors such as automotive and aerospace.

Advanced Signaling and Digitalization

Alongside modern trains, the signaling infrastructure is being upgraded:

- Kavach System: An indigenously developed Train Collision Avoidance System (TCAS).

- Centralized Traffic Control for better operational efficiency.

- Digital Interlocking replacing old mechanical systems.

- IoT and AI-powered predictive maintenance to improve safety and reduce downtime.

Digitalization ensures reliability, punctuality, and passenger safety — essential for India’s vision of becoming a rail technology leader.

Sustainability in Train Manufacturing

Modern rail manufacturing is aligned with green mobility goals:

- Electrification Drive: Indian Railways aims for 100% electrification by 2030.

- Lightweight Materials: Use of aluminum and stainless steel to reduce energy consumption.

- Renewable Integration: Solar-powered train components and station infrastructure.

This push for sustainability opens opportunities for innovation in materials engineering, renewable integration, and waste reduction in manufacturing.

The Role of On-Demand Manufacturing in Railways’ Future

Large-scale train manufacturing requires custom components, prototypes, and rapid production capabilities — an area where on-demand manufacturing plays a vital role.

Advantages of On-Demand Manufacturing for Railways:

- Faster Development Cycles – Rapid prototyping and production reduce design-to-deployment timelines.

- Reduced Inventory Costs – Components are produced only when needed.

- Customization – Tailor-made solutions for different routes, passenger needs, and metro projects.

- Localized Supply – Shorter lead times and better quality control.

With on-demand manufacturing, railway OEMs and metro projects can streamline supply chains, cut costs, and innovate faster — making it a perfect fit for India’s railway transformation.

Mechkonnect: Your Partner in Railway Manufacturing Excellence

At Mechkonnect, we understand that the future of Indian railways depends on precision, innovation, and speed in manufacturing. As a trusted on-demand manufacturing partner, we support railway OEMs, metro projects, and component suppliers with:

- High-quality, precision-engineered parts for trains, metros, and signaling systems.

- Rapid prototyping for new designs and product improvements.

- Material expertise — from lightweight aluminum to high-strength steel.

- Flexible manufacturing capacity to meet urgent project deadlines.

By partnering with Mechkonnect, you gain reliability, efficiency, and scalable manufacturing solutions that align perfectly with the Make in India vision.

The Future: India as a Global Rail Manufacturing Hub

Looking ahead, India’s railway transformation is set to accelerate:

- Export Opportunities: Indian-made coaches and signaling systems for Southeast Asia, Africa, and Latin America.

- High-Speed Rail: Indigenous participation in the Mumbai-Ahmedabad bullet train project will boost local expertise.

- Digital Twin Technology: Simulating train systems before manufacturing for better performance and safety.

- AI-Powered Predictive Maintenance: Reducing downtime and improving operational life cycles.

If the momentum continues, India won’t just meet domestic needs — it will export world-class rail technology across the globe.

Final Thoughts

The transformation of India’s railways is not just a modernization story; it is an industrial revolution powered by Make in India, technological innovation, and sustainable practices. Indigenous high-speed trains, metro manufacturing, digital signaling, and on-demand production are turning India into a self-reliant, globally competitive rail manufacturing hub.

With partners like Mechkonnect, railway manufacturers can innovate faster, reduce costs, and maintain world-class quality — ensuring that India’s railways remain a symbol of speed, safety, and sustainability for decades to come.