Quality Control in On-Demand Manufacturing: Ensuring Excellence in Every Project

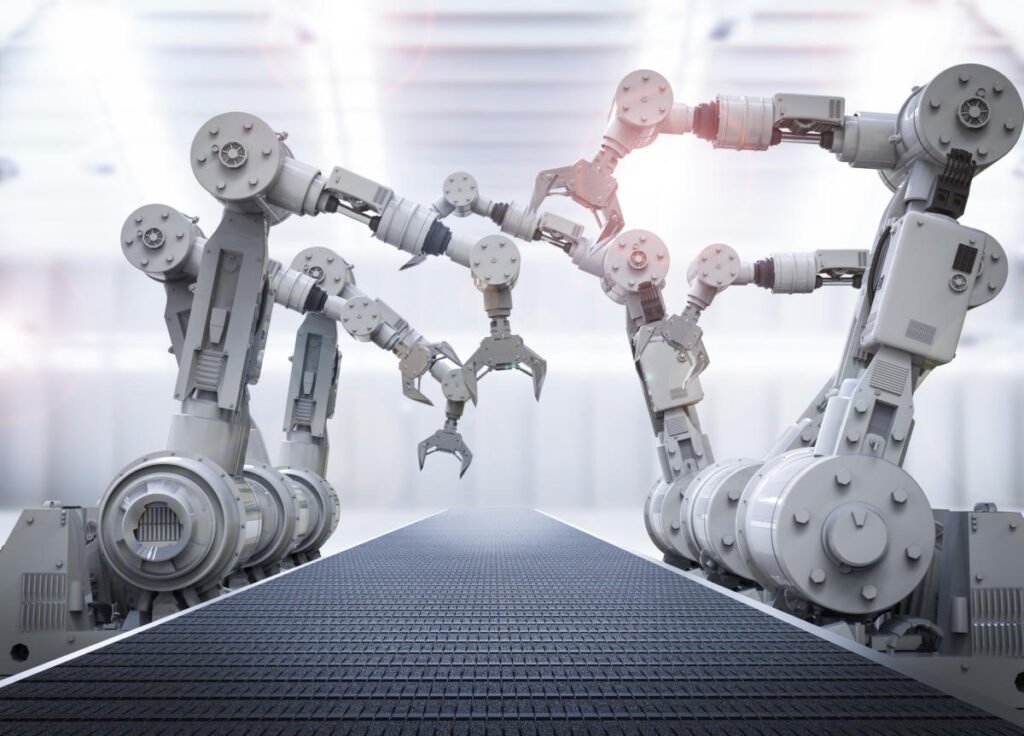

In modern and fast manufacturing, on-demand production has become a powerful solution. Whether it’s rapid prototyping, small-batch production, or customised components, on-demand manufacturing offers flexibility, speed, and cost-effectiveness. However, maintaining quality remains paramount, especially when producing parts with tight tolerances or critical applications.

This article delves into the significance of quality control (QC) in on-demand manufacturing and explores best practices to ensure excellence

What Does Quality Control Do in Manufacturing?

Quality control is the process that ensures products meet predefined standards and specifications, minimising defects and ensuring customer satisfaction. Here’s how QC impacts on-demand manufacturing.

- Defect Prevention

By adhering to strict processes and standards, QC prevents defects from entering the production cycle. Catching and addressing issues early reduces rework, scrap, and associated costs

2. Cost Management

Effective QC minimises waste, streamlines processes, and optimises resource utilisation. It directly impacts the bottom line by reducing labour costs, material waste, and rejections.

3. Brand Reputation

Defective products harm the brand reputation and customer trust. QC safeguards against subpar components, ensuring consistent quality and reliability

Quality Control vs. Quality Assurance

While these terms are often used interchangeably, they signify different characteristics of quality management:

Parameters | Quality Control | Quality Assurance |

Focus | Inspection and verification at the machine or assembly level. | Preventing defects before they occur.

|

Objective | Detect, record, and categorize defects. | Analyze trends, implement process changes, and improve overall quality.

|

Tools | Digital calipers, automated inspection systems, statistical process control (SPC). | Histograms, control charts, Pareto charts.

|

Timing | Reactive (after production). | Proactive. |

Role in On-Demand Manufacturing | Ensures compliance with specifications.

| Part of a holistic improvement system (e.g., Total Quality Management, Lean, Six Sigma). |

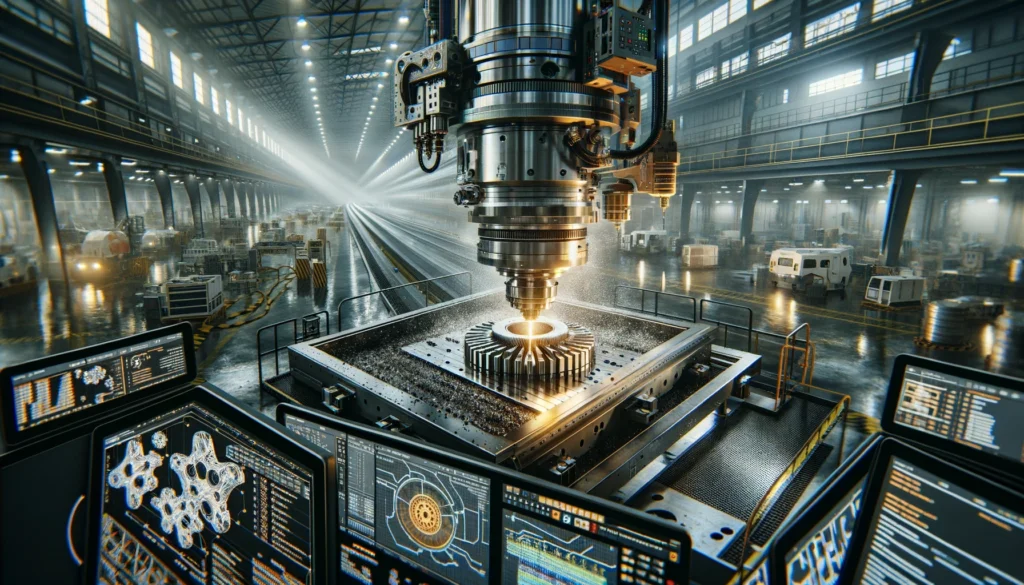

Key Practices for Effective Quality Control

Standardized Processes: Adherence to standardized work instructions is crucial. Any deviation can lead to out-of-spec products and waste.

Data-Driven Insights: Collect data on part quality using tools like MachineMetrics. Understand cycle times, part counts, and reject reasons. Identify bottlenecks and waste areas.

Early Detection: In connected factory ecosystems, digital verification moves closer to production. Detecting defects early prevents downstream issues.

High-Tolerance Industries: In aerospace, medical devices, and other high-tolerance sectors, QC directly impacts operational performance and safety.

Total Quality Management (TQM): Implement formal quality best practices. Total Quality Management (TQM) places a strong emphasis on the principle of continuous improvement and actively engages all employees in this endeavour.

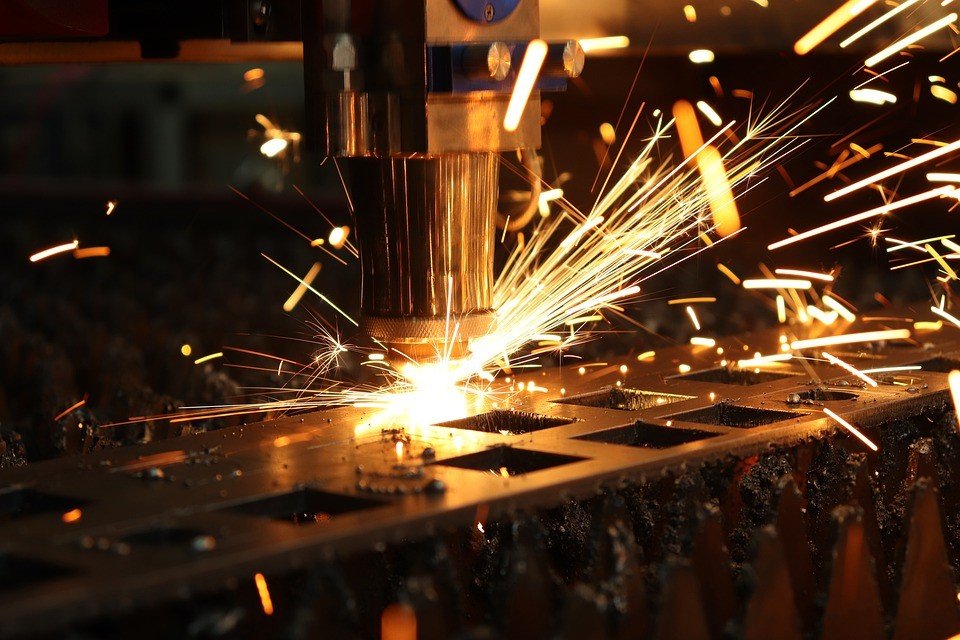

Quality control in on-demand manufacturing is non-negotiable. It ensures that each component meets specifications, maintains cost efficiency, and upholds safety. By embracing QC practices, manufacturers can deliver defect-free products, protect their brand, and enhance customer satisfaction. As the industry evolves, QC remains the backbone of excellence in every project.

Quality is a commitment to excellence, not just a checkbox.

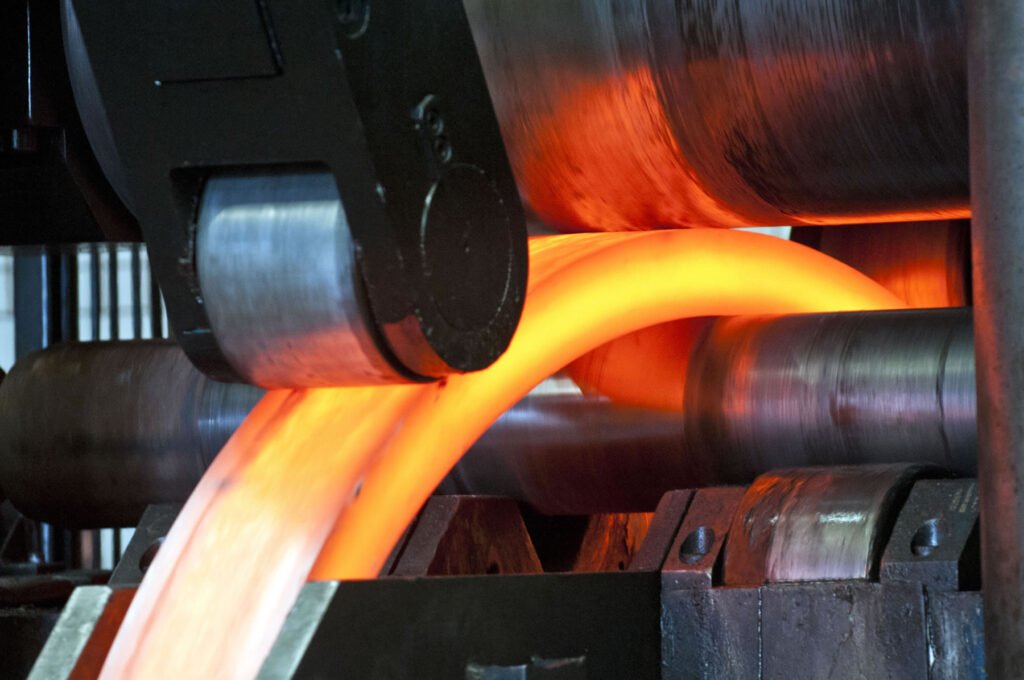

Mechkonnect, a leading player in the field of contract manufacturing, meticulously ensures quality control in every project. Their team of skilled engineers and technicians translates project specifications into a methodically planned production process. Regular communication and rigorous quality checks are integral to their approach. By adhering to stringent standards, Mechkonnect ensures that the final product consistently meets or exceeds expectations. Whether it’s metal fabrication or other precision manufacturing tasks, their commitment to excellence remains unwavering.

Ready to elevate your manufacturing process? Contact Mechkonnect today and experience quality-driven excellence firsthand!

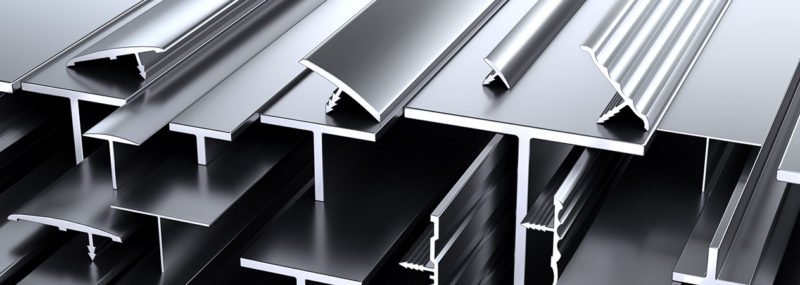

Top-Quality Fabrication Metal for Efficient Production

MechKonnect specializes in fabrication metal and on-demand manufacturing, ensuring top-quality results through strict quality control. Their expertise in fabrication metal provides high-precision solutions for custom parts and large-scale production. By utilizing advanced fabrication metal techniques, MechKonnect reduces waste, cuts costs, and speeds up time-to-market. With a focus on reliability and durability, MechKonnect delivers exceptional fabrication metal solutions that meet the highest industry standards, ensuring client satisfaction in every project. Whether for complex or simple tasks, their fabrication metal services offer unmatched precision and efficiency.

Recent Post