Material Selection for CNC Projects: Beyond Metals

VMC Machines and Material Selection: Expanding Your Project Possibilities Beyond Traditional Metals.

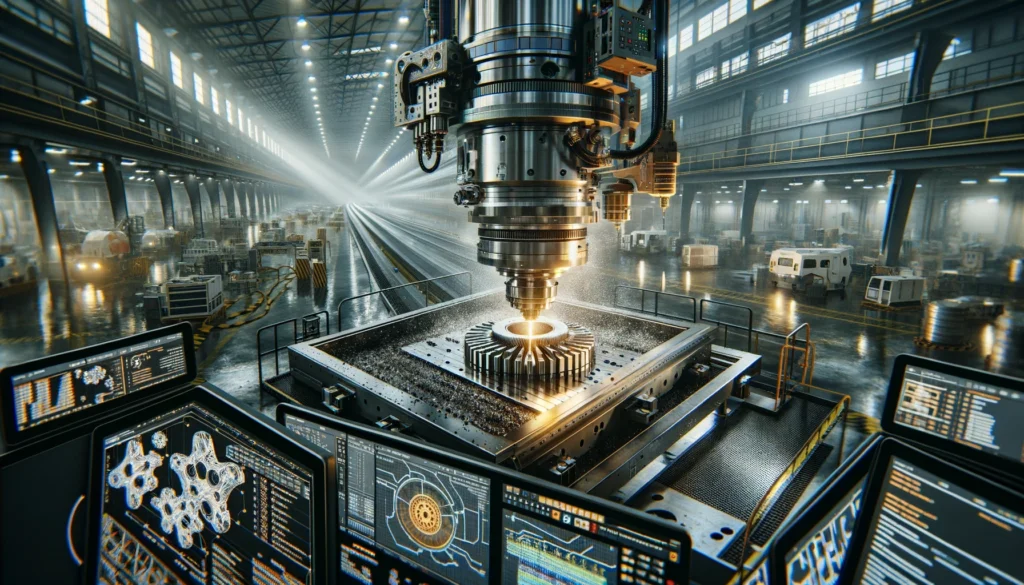

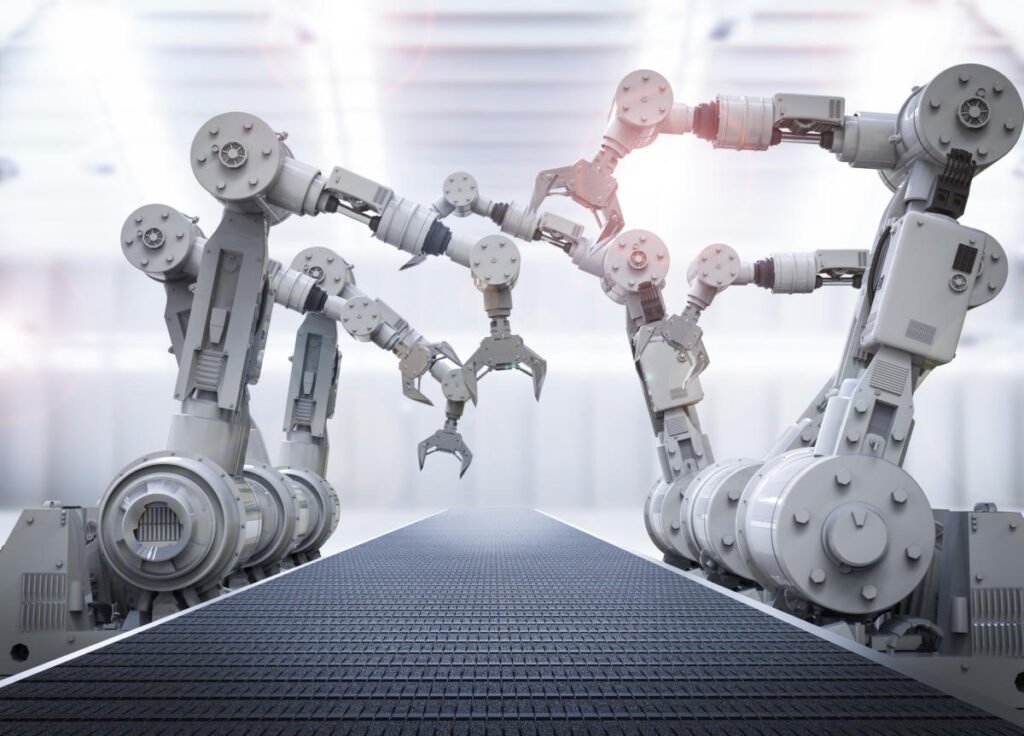

Computer Numerical Control (CNC) machining has revolutionised manufacturing processes across various industries. From aerospace components to intricate electronic parts, CNC machines offer precision, speed, and versatility. However, the success of any CNC project hinges on a critical decision: material selection. While metals have traditionally dominated this field, a fascinating array of non-metallic materials deserve exploration. In this article, we delve beyond metals, considering plastics, titanium, wood, foam, and composites. Let’s unlock new possibilities and discover how material choices impact CNC projects.

VMC machines are essential for precision CNC machining, but selecting the right material is just as crucial to the success of your CNC machining projects. In this guide, we’ll explore material selection beyond traditional metals, including advanced plastics, composites, and more. Whether you’re working on small-scale or large-scale VMC machine projects, understanding the diverse materials available can optimize the performance, durability, and cost-efficiency of your CNC machining. Learn how material selection for VMC machines and CNC machining can unlock new possibilities and improve your machining outcomes.

Factors to Consider in Material Selection

Before we dive into specific materials, let’s address essential factors that influence material decisions:

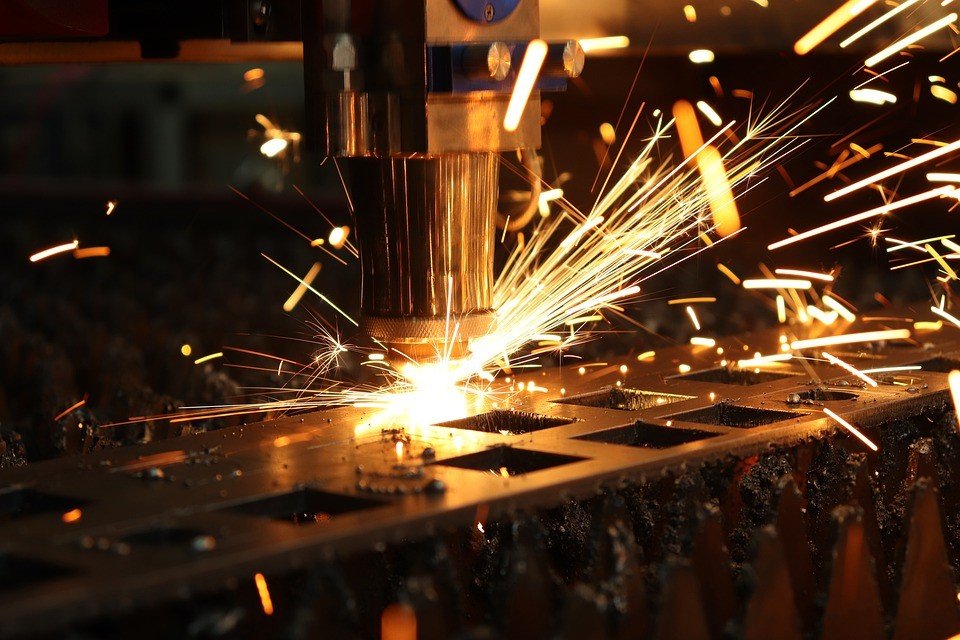

- Machining Environment

The environment in which CNC machining occurs significantly impacts material performance. Consider the following:

Temperature: Some materials may chip or crack at high machining temperatures.

Tool Wear: Excessive tool wear can occur if cutting speeds are too high.

Coolants and Lubricants: Compatibility with materials is crucial when using coolants or lubricants.

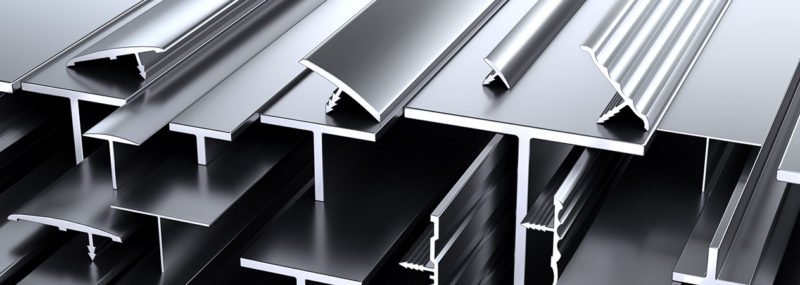

- Part Weight

Part weight affects cost, performance, and manufacturability. Heavier parts require more material, increasing production costs. Opting for materials with lower density, such as aluminium or magnesium, can reduce weight and overall expenses.

Materials Beyond Metals

- Plastics

Plastics have gained prominence in CNC work due to their versatility. Let’s explore some notable plastic materials:

Polyethylene

- Resistant to chemicals and heat.

- Widely used in applications requiring durability and corrosion resistance.

PVC (Polyvinyl Chloride)

- Handles heat well and exhibits chemical resistance.

- Suitable for various CNC projects.

- Titanium

Titanium deserves special mention for its exceptional properties:

- Lightweight

- Ideal for weight-sensitive applications.

- Used extensively in aerospace and medical devices.

- High Strength

- Comparable to steel but significantly lighter

- Perfect for components where the strength-to-weight ratio matters.

- Corrosion Resistance

- Thrives in harsh environments (underwater, space radiation).

- Valuable for marine and aerospace applications.

- Wood and Foam

CNC machining extends beyond metals and plastics. Let’s explore unconventional materials:

Wood

- Ideal for artistic creations, decorative elements, and intricate designs.

- Wood CNC projects often blend craftsmanship with technology.

Foam

- Used in prototyping and architectural models.

- Lightweight and easy to shape, making it ideal for intricate designs.

- Composites

Composite materials combine different constituents to offer unique properties:

Carbon Fiber Composites

- Exceptional strength-to-weight ratio.

- Commonly used in high-performance applications like sports equipment and automotive parts.

Fiberglass Composites

- Good electrical insulation.

- Suitable for components requiring both strength and electrical properties.

Material selection for CNC projects involves a delicate balance of strength, machinability, and application requirements. Beyond metals, explore plastics, titanium, wood, foam, and composites. Each material brings its strengths and limitations. Whether you’re crafting intricate jewellery or building robust industrial components, the right material choice can elevate your CNC project. Remember, precision begins with the right material!

Unleashing the Power of CNC Machining with Mechkonnect

At the heart of our offerings lies CNC machining. We harness the power of precision engineering, delivering accurate and finely produced components that meet the most stringent industry standards. Our Vertical Machining Centers (VMC) equipped with cutting-edge technology bring designs to life with unparalleled accuracy and efficiency. From aerospace to automotive, electronics to medical devices, our CNC VMC machining caters to diverse sectors, ensuring customized solutions for unique demands.

VMC machines at Mechkonnect enable precision CNC machining across industries, from aerospace to medical devices, with customized solutions for diverse materials.While metals have traditionally dominated CNC projects, Mechkonnect goes beyond. We explore materials like plastics, titanium, wood, foam, and composites. Each material brings its strengths and limitations, allowing us to unlock new possibilities in CNC machining. Whether it’s intricate artistic creations in wood or high-strength components in titanium, we tailor solutions to elevate your projects.

At MechKonnect, we believe that anything that can be made can be made better. Let’s create precision together! Ready to transform your metalworking vision into reality? Reach out to us.

Recent Post