Investment Casting (Lost Wax): A Comprehensive Guide with 3D Printing and CAD Integration

What is Investment Casting?

Definition and Historical Context

Investment casting also referred to as precision casting or cire perdue (French for “lost wax”), dates back thousands of years. Ancient civilizations, including the Egyptians and Chinese, used this technique to create intricate metal artifacts. The process involves creating a detailed wax pattern, encasing it in a ceramic shell, melting out the wax, and pouring molten metal into the resulting cavity. The term “investment” refers to the ceramic mold that surrounds the wax pattern during casting.

Key Terminology: Lost Wax, Pattern, Mold, and Shell

Lost Wax: The wax pattern that serves as a replica of the final metal part.

Pattern: The wax model that is created by skilled artisans or through 3D printing.

Mold: The ceramic shell formed around the wax pattern.

Shell: The hardened ceramic mold that withstands high temperatures during casting.

The Investment Casting Process

Pattern Creation

Artisan-Crafted Patterns: Skilled artisans sculpt the wax patterns by hand, paying attention to intricate details.

Modern Techniques: 3D printing and computer-aided design (CAD) are used to create precise patterns.

Mold Preparation

Assembly: The wax patterns are attached to a central wax sprue.

Ceramic Coating: The assembly is dipped in a ceramic slurry multiple times to build up the shell.

Drying and Hardening: The coated assembly is dried and heated to harden the ceramic shell.

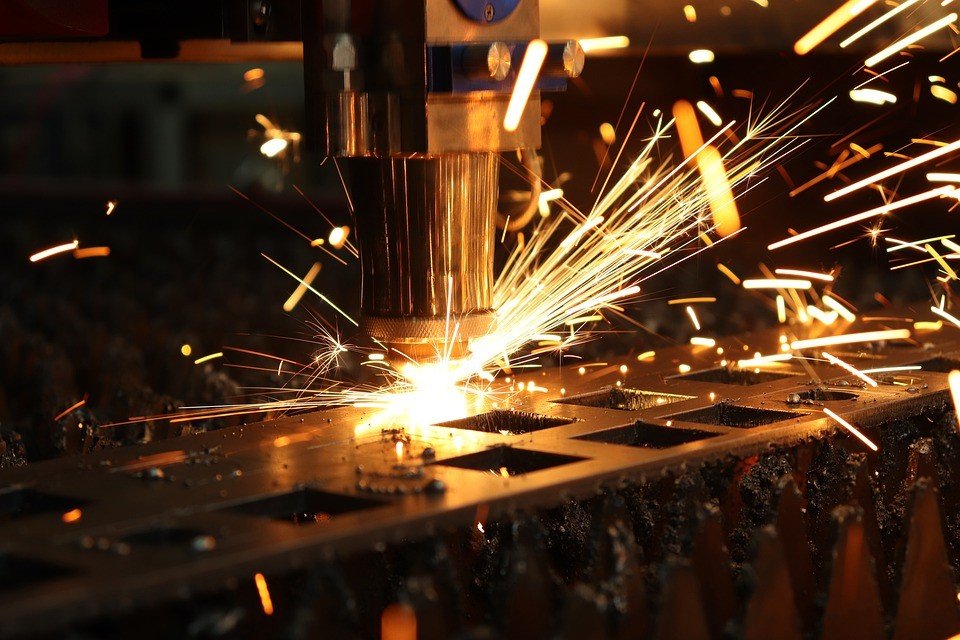

Wax Removal and Shell Formation

Dewaxing: The ceramic shell is heated to melt and remove the wax, leaving behind a hollow mold.

Shell Baking: The empty shell is further heated to strengthen it and remove any remaining moisture.

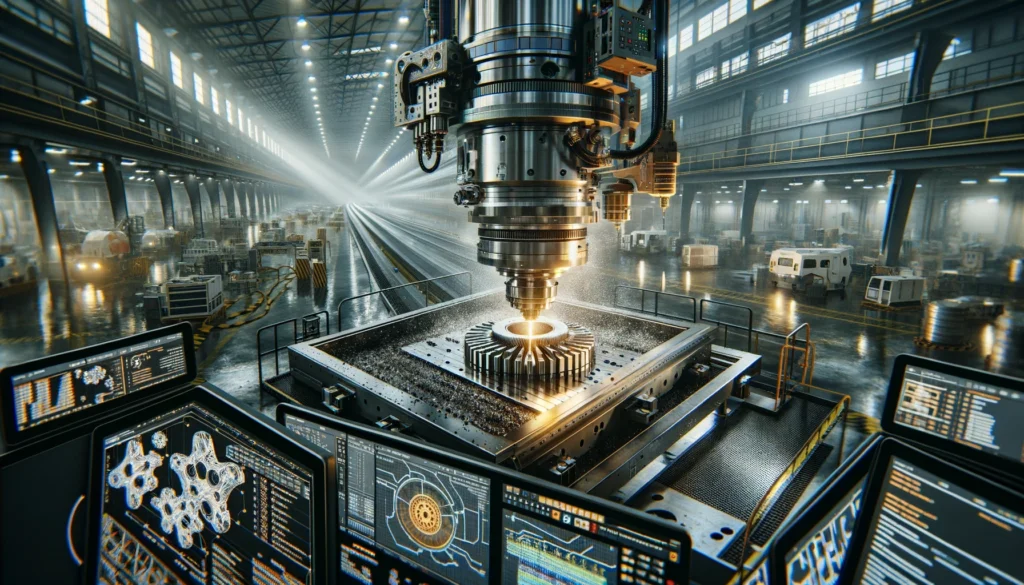

Melting and Pouring

Melting: The chosen metal (e.g., stainless steel, aluminium, or bronze) is melted in a furnace.

Pouring: The molten metal is poured into the preheated ceramic shell.

Cooling and Shell Breakout

Cooling: The metal solidifies within the shell.

Shell Breakout: The ceramic shell is broken away, revealing the cast metal part.

Applications of Investment Casting

Aerospace and Defense

Investment casting is widely used for turbine blades, engine components, and structural parts in aircraft and rockets.

Automotive Industry

Automakers utilize investment casting for engine parts, transmission components, and suspension systems.

Jewelry and Art

Artists and jewellers create intricate designs using investment casting for gold, silver, and other precious metals.

Medical Devices

Implants, dental fixtures, and surgical instruments benefit from the precision of investment casting.

Advantages of Investment Casting

- Investment casting allows for intricate geometries and tight tolerances.

- Various metals and alloys can be cast, offering flexibility in material selection.

- Investment casting produces smooth surfaces with minimal post-processing.

- While tooling costs are higher, batch production can be cost-effective.

Limitations and Challenges

Shrinkage, porosity, and limited part size are challenges in investment casting.

To sum up,

Investment casting continues to play a crucial role in modern manufacturing. As technology advances, innovations in materials, automation, and quality control will shape its future. Whether crafting a delicate jewellery piece or engineering critical aerospace components, the lost wax process remains a timeless and valuable technique.

Recent Post