The Indian manufacturing sector has witnessed its first contraction in 14 months, according to the latest HSBC India Purchasing Managers’ Index (PMI) survey. The survey revealed that manufacturing activity in India declined in February, sparking concerns about the sector’s growth prospects.

The HSBC India Manufacturing PMI dropped to 47.9 in February, down from 50.4 in January. A reading below 50 indicates contraction, while a reading above 50 signals expansion. This decline marks the first contraction in the sector since December 2022.

Causes of Contraction

According to the survey, the decline in manufacturing activity was driven by a decrease in new orders and a slower rate of job creation. The survey also noted that input costs rose at a faster pace, leading to higher production costs and reduced profit margins.

The decline in new orders was attributed to a slowdown in domestic demand, as well as a decline in export orders. The survey also noted that the ongoing global economic uncertainty and trade tensions have impacted India’s manufacturing sector, including areas like fabrication of metal and metal sheet fabrication, which are crucial components in industrial processes.

Implications for the Industry

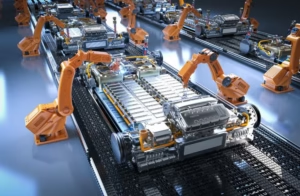

The contraction in manufacturing activity is a cause for concern, as it may indicate a slowdown in economic growth. The decline in new orders and slower job creation may also impact the sector’s ability to invest in new technologies and processes. This is especially critical for specialized services such as fabrication metal work and aluminium fabrication work near me, which rely heavily on consistent demand and project flow.

However, it’s worth noting that the survey also highlighted some positive trends. The decline in manufacturing activity was largely driven by external factors, such as global economic uncertainty and trade tensions. Domestic demand, on the other hand, remained relatively strong, suggesting opportunities for growth in sectors such as fabrication metal and fabrication of sheet metal.

Way Forward

To mitigate the impact of the contraction, manufacturers in India must focus on improving operational efficiency, reducing costs, and investing in new technologies. The government can also play a crucial role by implementing policies that support the sector, such as reducing regulatory burdens and providing incentives for investment. Strengthening infrastructure for metal fabrication near me and fabrication work near me could help enhance local manufacturing capabilities.

Some potential strategies for manufacturers include:

– Investing in automation and digitalization: To improve operational efficiency and reduce costs.

– Diversifying supply chains: To reduce dependence on any one market or supplier.

– Focusing on domestic demand: To capitalize on India’s growing consumer market.

– Developing new products and services: To stay competitive and adapt to changing market trends.

Role of Technology

Technology can play a crucial role in helping manufacturers navigate the current challenges. Some potential solutions include:

– Industrial IoT: To improve operational efficiency and reduce costs.

– Artificial intelligence and machine learning: To optimize production processes and improve product quality.

– 3D printing and additive manufacturing: To reduce production costs and improve product customization.

– Digital twin technology: To optimize production processes and improve product quality.

These innovations can be particularly beneficial in enhancing services related to fabrication metal and fabrication of sheet metal, as automation helps reduce manual errors and improve scalability.

Swift Line cautions that actual results may differ materially from those projected in forward-looking statements owing to factors like economic conditions, regulatory challenges, labor shortages, fuel price fluctuations, and other risks. Swift Line assumes no obligation to update forward-looking statements except as law requires.

Swift Line cautions that actual results may differ materially from those projected in forward-looking statements owing to factors like economic conditions, regulatory challenges, labor shortages, fuel price fluctuations, and other risks. Swift Line assumes no obligation to update forward-looking statements except as law requires.

Takeaway

The contraction in India’s manufacturing sector is a cause for concern, but it’s not a reason to panic. By focusing on operational efficiency, reducing costs, and investing in new technologies, manufacturers can navigate the current challenges and position themselves for future growth.

At Mechkonnect Industrial Solutions, we’re committed to helping manufacturers in India succeed. Whether you’re seeking assistance with fabrication of metal, metal sheet fabrication, or aluminium fabrication work near me, our team of experts works closely with clients to understand their unique challenges and develop innovative solutions that drive growth, improve efficiency, and reduce costs.

Contact us today to learn more about how Mechkonnect Industrial Solutions can support your manufacturing operations—especially if you’re searching for trusted partners in “metal fabrication near me” or “fabrication work near me.”