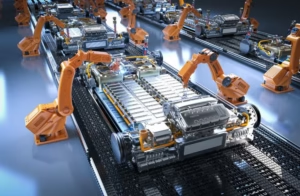

From immersive training modules to real-time maintenance assistance, AR in manufacturing is no longer a futuristic concept—it’s a practical tool reshaping how work gets done in modern smart factory environments.

A Shift in Manufacturing Priorities

On-demand production models—whether in additive manufacturing, CNC machining, forging, or injection molding—depend heavily on the interplay between precision equipment and skilled operators. Traditional methods of operator training and machine maintenance struggle to keep up with the rapid iteration and high mix-low volume nature of this sector.

The risks are considerable: a minor error by an undertrained operator or delayed maintenance on a key machine can cause cascading delays across an entire production line. That’s where AR-based maintenance tools and AR-enabled training systems step in, offering real-time, visual, and hands-free support tailored for fast-paced industrial environments.

Enhancing Maintenance Efficiency with AR

Real-Time Troubleshooting and Predictive Support

In a high-stakes environment where uptime is king, unplanned machine failure is a costly liability. A 2023 report from Deloitte notes that the average manufacturer loses 5–20% of productivity due to downtime. AR for predictive maintenance can significantly mitigate this.

AR solutions integrate with IoT-enabled machines to overlay sensor data—temperature, vibration levels, fluid pressures—onto the equipment in real time. This allows technicians to identify anomalies before a breakdown occurs. Instead of relying on manuals or desktop diagnostics, workers see exactly where the issue lies, how to fix it, and what tools are needed—all while viewing the machine itself.

Remote Expert Collaboration

With AR in industrial maintenance, geographical limitations no longer hinder problem resolution. A technician can connect through AR glasses to a remote expert who sees what they see, annotates their field of view, and guides them step by step. This remote assistance via AR drastically reduces the need for expert site visits, cuts downtime, and improves first-time fix rates.

Improved Workflow Accuracy

Interactive AR overlays guide technicians through standardized procedures—whether it’s lubricating a bearing, aligning a motor shaft, or calibrating a 3D printer. It eliminates guesswork and reduces reliance on printed SOPs or verbal guidance, both of which are prone to misinterpretation.

Revolutionizing Operator Training Through Augmented Reality

Immersive and Scalable Training

Training new hires on complex machinery can take weeks. AR for operator training reduces this to days. Trainees use AR headsets or tablets to follow 3D walkthroughs, engage in interactive simulations, and perform virtual tasks in a realistic factory setting. This accelerates retention and comprehension far more effectively than conventional classroom instruction.

A recent PwC study found that AR training increases learning retention by 75% and reduces errors in early production tasks by up to 50%.

Safety Without Compromise

AR allows operators to learn and practice dangerous or high-risk tasks in a zero-risk environment. For instance, in casting and molding operations, where heat and pressure pose hazards, AR simulations can train workers in safety protocols, emergency procedures, and equipment handling without exposing them to real-world risk.

Standardized Knowledge Across Facilities

Whether you’re running one facility or twenty, AR-based training ensures consistent knowledge transfer. All operators receive identical instruction, visual cues, and task validation—minimizing variance and boosting overall production quality.

Real-World Use Cases in On-Demand Manufacturing

- CNC Maintenance: Technicians can view internal machine diagnostics, tool path deviations, and component replacements through AR headsets while performing hands-on adjustments.

- 3D Printing Calibration: AR projects real-time extrusion paths, bed-leveling visuals, and print success rates for operators working with complex polymer or metal printers.

- Assembly Line Training: Workers can follow precise AR-guided sequences—bolt torque, wiring order, inspection checkpoints—especially useful in high-mix low-volume product lines.

- Die Maintenance in Forging: By projecting internal die geometry and cooling channel layouts, AR enables maintenance teams to perform accurate checks and repairs without disassembly.

Implementation Considerations

While the advantages are clear, deploying AR in manufacturing environments requires thoughtful planning. Challenges include:

- Integration with Manufacturing Execution Systems (MES) and IoT platforms

- Ensuring network stability for live data streaming

- Device durability in harsh factory conditions

- Developing custom AR content that’s accurate and user-friendly

Still, the trajectory is promising. With AR hardware becoming more affordable and cloud-based AR platforms emerging, adoption is increasing among small and medium manufacturing enterprises (SMEs)—not just large OEMs.

The Competitive Edge of AR in Industry 4.0

As Industry 4.0 continues to reshape manufacturing, augmented reality in operator training and maintenance will no longer be optional—it will be fundamental. It’s a force multiplier for human intelligence, enabling manufacturers to scale knowledge, reduce downtime, and maintain exceptional quality across every batch, every shift.

By investing in smart factory solutions like AR, manufacturers not only gain operational efficiency but also improve workforce engagement, safety, and agility—three pillars essential for succeeding in on-demand production models.

Mechkonnect Industrial Solutions: Engineering the Future with AR

At Mechkonnect Industrial Solutions, we’re at the forefront of merging traditional manufacturing craftsmanship with advanced digital technologies. With core competencies in CNC machining, casting, fabrication, and rapid prototyping, we’ve extended our expertise to deliver AR-based maintenance and operator training solutions tailored to modern industrial needs.

Whether you’re scaling up your operations or integrating digital transformation into your production floor, Mechkonnect supports your journey with domain expertise, tech innovation, and hands-on implementation. We help clients reduce machine downtime, upskill their workforce, and stay competitive in an era where manufacturing excellence is defined by speed, accuracy, and intelligence.