Case Study: IIT Bombay RoboWar Competition and Mechkonnect's Assistance in the Robot’s Welding

The Scenario

A group of Russian students participating in IIT Bombay’s RoboWar competition encountered a challenge: repairing their robot’s body, made of a specialized titanium material.

Mechkonnect, a company specializing in industrial connections, played a crucial role in helping them overcome this obstacle and participate in the competition successfully.

Key Players

Students: Participants from Russia in IIT Bombay’s RoboWar competition

Enabler: Mechkonnect, a company specializing in industrial solutions

Organizer: RoboWar Competition, IIT Bombay

The Challenge

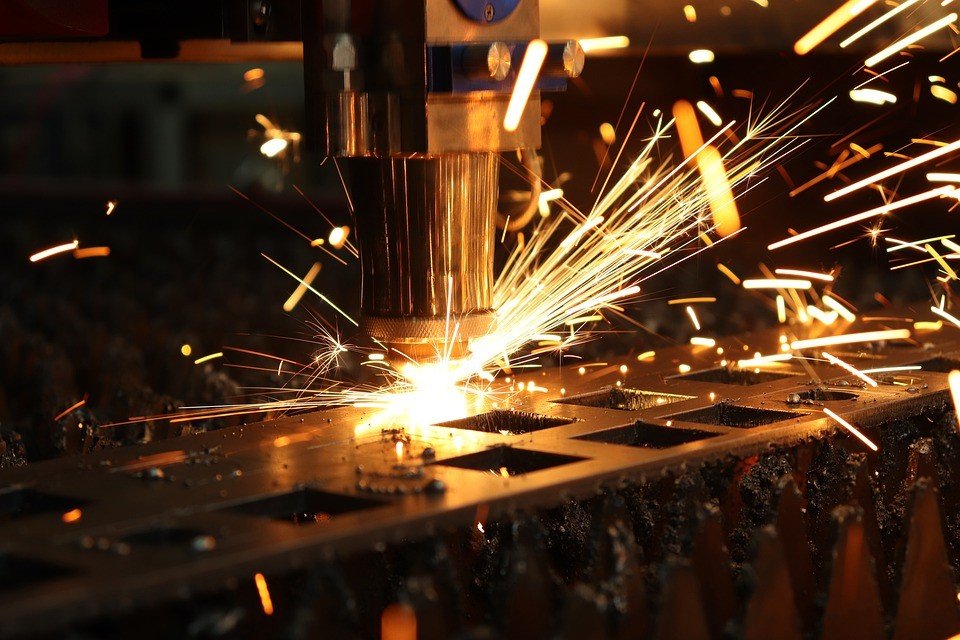

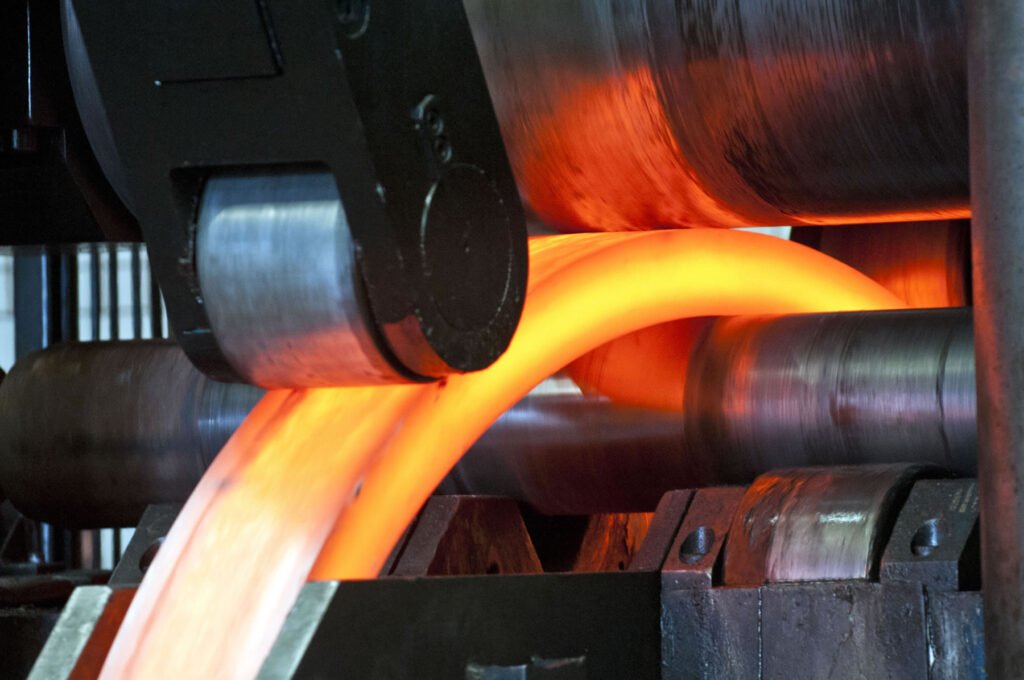

The participants from Russia made a robot for IIT Bombay’s Robowar competition. The robot’s body was made of a robust material of titanium. However, during the competition, it sustained damages. Using a conventional welding technique was not impactful given the unique properties of the robot. This threatened their participation and potential success in the competition.

Mechkonnect’s Approach

Upon learning about the students’ predicament, Mechkonnect stepped in to assist. Their expertise in industrial connections and knowledge of specialized materials allowed the vendors to repair the robot with precision.

First, the students needed to identify the right vendor. Having vast practical knowledge, network, and understanding of the local market, Mechkonnect was the fixed choice to resolve the robot’s issue. Mechkonnect helped in providing a vendor who was equipped to conduct the titanium welding using the TIG (Tungsten Inert Gas) method. This was a suitable method for this particular material.

Second, Mechkonnect bridged the language barrier between the Russian students and the local vendor, ensuring smooth communication and a clear understanding of the repair requirements.

Lastly, Mechkonnect was able to offer technical guidance throughout the repair process, ensuring the robot’s body was mended correctly and safely.

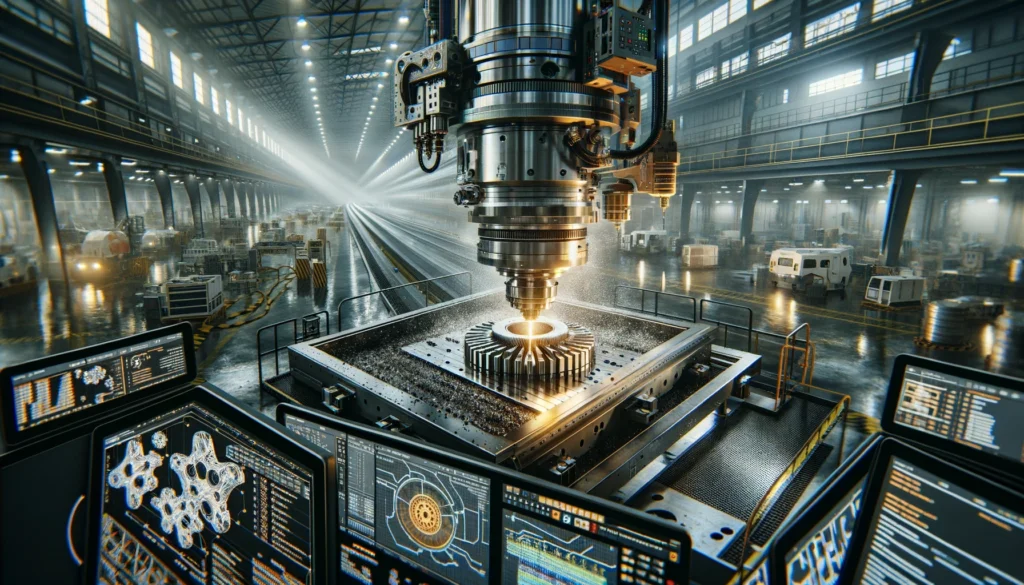

Welding Photo- take from WhatsApp group

The Outcome

Due to Mechkonnect’s intervention, the students were able to:

With the TIG Welding technique, the robot’s body was repaired successfully. This allowed the robot to compete again. As the robot was functional, the students could continue their participation in the Robowar and showcase their skills. Additionally, they were able to gain valuable experience and understand the importance of resourcefulness, local market network, collaboration, and seeking expert guidance when facing challenges.

Group Photo

Explore Manufacturing Opportunities with Mechkonnect

Having a cumulative experience of 10+ years, Mechkonnect uses its expertise in manufacturing and consulting through an impressive network of vendors. Mechkonnect has been working in the actual local market which has helped in leveraging the connections with multiple vendors across the industries. Knowing the nitty-gritty of the vendors as well as the challenges faced by client companies, Mechkonnect becomes an enabler and finds a ground for both parties. Mechkonnect, through its consultancy, helps in identifying the loopholes and troubleshooting the challenges in manufacturing, namely, CNC machine, forging, 3D printing, welding, fabrication, moulding, and casting.

If you’re facing challenges with an existing product or machinery or need consultancy in manufacturing a product, we are here to help! With our experience and expertise, we will guide you throughout the process. Explore manufacturing opportunities with us today!

Recent Post