A Guide to CNC Milling vs. CNC Turning for On-Demand Production

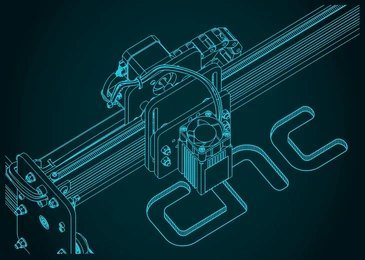

In on-demand manufacturing, CNC (Computer Numerical Control) machine plays a crucial role in producing high-quality parts quickly and efficiently. Two popular CNC processes are milling and turning, each with its unique strengths and applications.

In this guide, we will delve into the differences between CNC milling and CNC turning, exploring their processes, advantages, and ideal use cases for on-demand production.

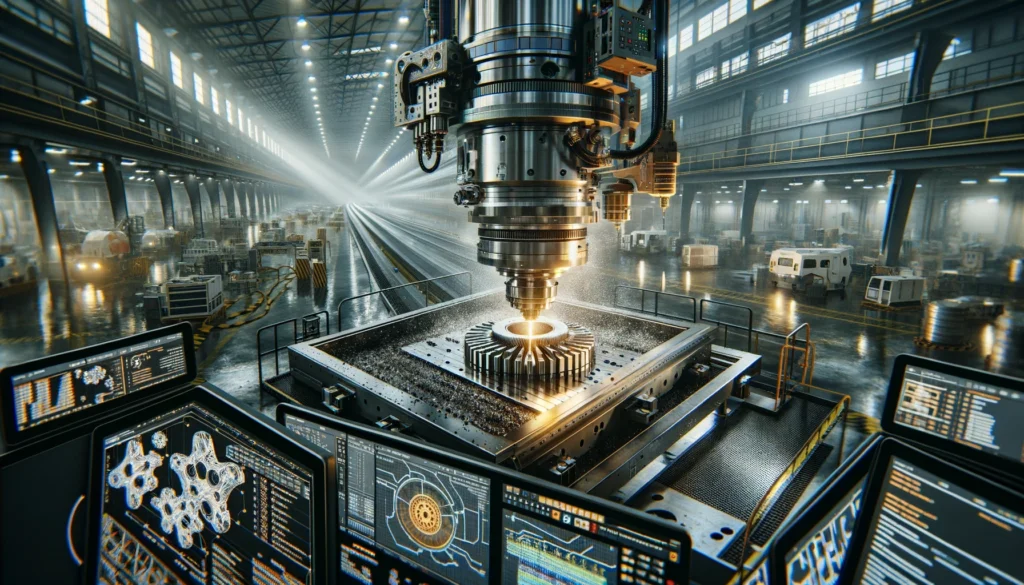

Understanding CNC Milling

CNC milling is a machining process that uses rotating cutting tools to remove material from a workpiece. The milling machine moves the tool in three dimensions, creating complex shapes and designs. Milling can be performed on various materials, including metals, plastics, and composites.

Explore the key differences between CNC milling and CNC turning in on-demand production at MechKonnect. Our guide explains how CNC machine are used in both processes to create precise, high-quality components. Whether you’re looking for the versatility of CNC milling or the efficiency of CNC turning, MechKonnect provides expert insights on selecting the right CNC machine for your project. With advanced CNC machining technologies, we offer customized solutions that meet your specific manufacturing needs.

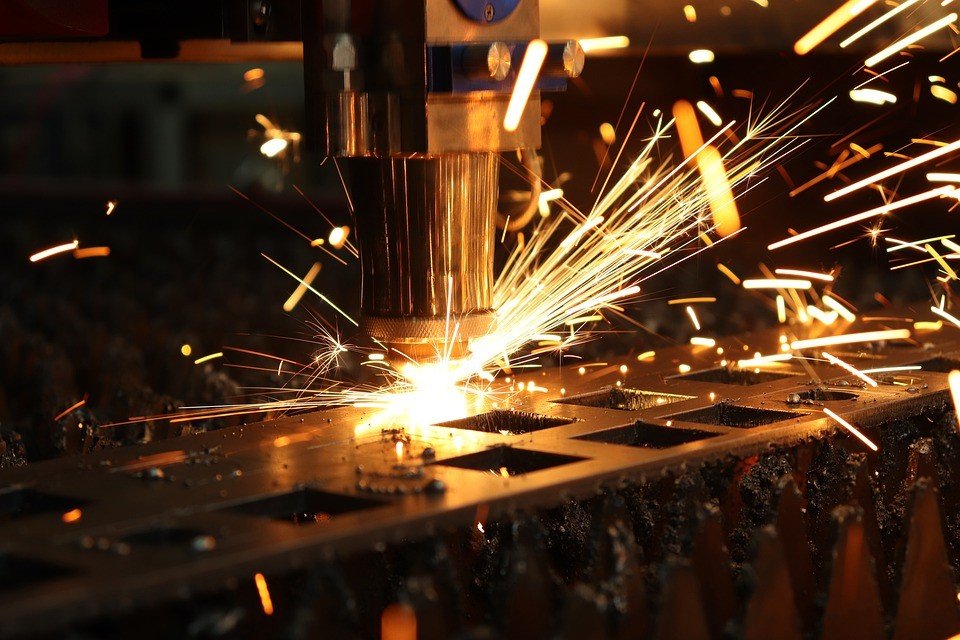

Understanding CNC Turning

CNC turning, also known as lathe machining, uses a single-point cutting tool to remove material from a rotating workpiece. The turning process creates symmetrical, rounded, or cylindrical parts, ideal for producing shafts, pipes, and other rounded components.

Main Distinctions Between CNC Milling and CNC Turning

Factors | CNC Milling | CNC Turning |

Machine Configuration | Milling machines have a stationary workpiece and a moving tool | Turning machines have a rotating workpiece and a stationary tool. |

Tooling | Milling uses rotating cutting tools | Turning uses single-point cutting tools. |

Material Removal | Milling removes material in three dimensions | turning removes material in a single plane. |

Part Complexity | Milling can produce complex shapes and designs | turning is ideal for symmetrical, rounded parts. |

Advantages of CNC Milling

- 1. Complexity: Milling can produce intricate designs and shapes.

- Material Versatility: Milling can work with various materials.

- Precision: Milling achieves high precision and accuracy.

- Precision: Milling achieves high precision and accuracy.

Advantages of CNC Turning

- Speed: Turning is generally faster than milling for symmetrical parts.

- Efficiency: Turning requires less tooling and setup time.

- Cost-Effective: Turning is often more cost effective for large quantities of simple parts.

Choosing Between CNC Milling and CNC Turning for On-Demand Production

For intricate and complex shapes, the milling process is an excellent choice. On the other hand, turning is best suited for producing symmetrical parts with relative ease. When working with a variety of materials, milling offers the flexibility to handle diverse materials. Turning, on the other hand, is particularly well-suited for working with metals and plastics. For large quantities of parts, turning is a more efficient option, whereas milling is preferable for manufacturing small batches or prototypes. Considering lead time, milling is known for its ability to deliver shorter lead times, while turning is recognized for its faster overall production.

On-Demand Manufacturing Considerations

When considering on-demand manufacturing, it’s essential to carefully assess the following aspects:

- Flexibility: CNC milling presents a superior level of adaptability, allowing for seamless design modifications and intricate detailing. This makes it an ideal choice for projects that demand frequent design changes or intricate component designs.

- Scalability: CNC turning is particularly well-suited for large-scale production, providing the efficiency and precision required for high-volume manufacturing projects.

- Cost: In scenarios involving small batch production or the creation of complex parts, CNC milling may prove to be more cost-effective due to its ability to efficiently handle intricate designs and smaller production runs.

In conclusion, CNC milling and CNC turning are both essential processes in on-demand manufacturing, each with its unique strengths and applications. Understanding the differences between these processes enables manufacturers to choose the best approach for their specific needs, ensuring efficient and effective production. By considering part design, material, quantity, and lead time, manufacturers can optimize their CNC machining processes for on-demand production success.

Want to start a CNC Milling or CNC Turning Project? Get in touch with us today!

.

Recent Post