Precision fabrication of metal techniques are pivotal in shaping the future of the ever-evolving manufacturing arena. Among the diverse materials used in this field, ceramics, glass, and the fabrication of metal stand out due to their unique properties, versatility, and applications.

In this comprehensive article, we delve into the intricacies of precision fabrication of metal for ceramics and glass, exploring cutting-edge methods in the fabrication of metal, and the role of Mechkonnect as a reliable partner for fabrication of metal and manufacturing on demand. Whether it’s the precision required for the fabrication of metal components or the specialized approaches for ceramics and glass, we discuss the various processes involved in fabrication of metal and how these materials contribute to advanced manufacturing. Through our expertise in fabrication of metal, we help clients achieve high-quality results in custom and on-demand production across industries.

Ceramics in On-Demand Manufacturing

Ceramics are non-metallic, inorganic materials that exhibit exceptional hardness, high melting points, and resistance to wear and corrosion. The use of these materials is widespread across industries such as healthcare, electronics, and aerospace.

Precision fabrication of ceramics involves several key techniques:

- Powder Processing:

- Ceramic powders are carefully selected and mixed to achieve desired properties.

- Techniques like slip casting, dry pressing, and isostatic pressing shape the green ceramic bodies.

- Sintering:

- Sintering at elevated temperatures fuses ceramic particles, resulting in densification and improved mechanical properties.

- Hot isostatic pressing (HIP) further enhances density and eliminates defects.

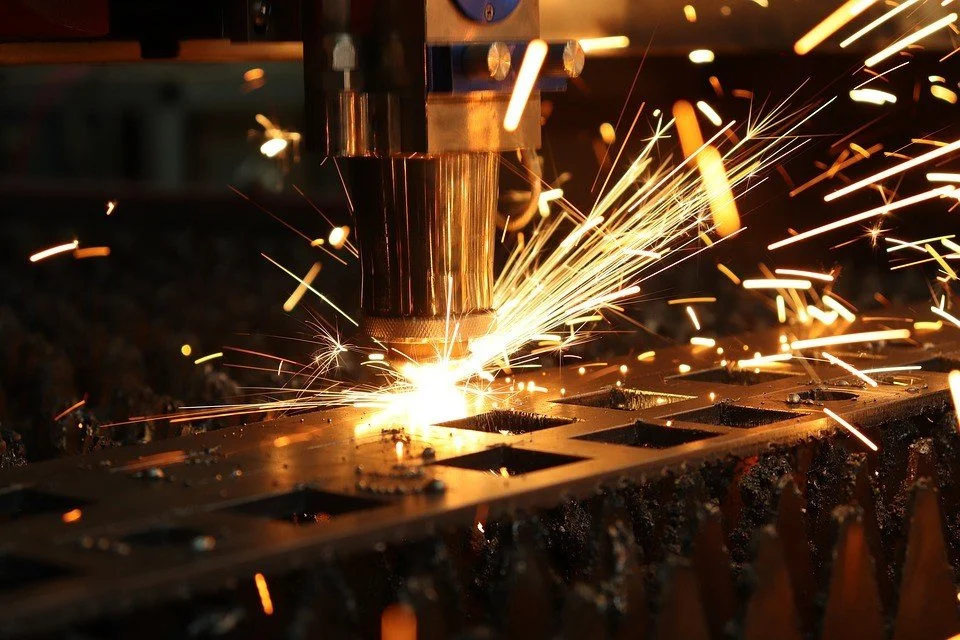

- Laser Machining:

- Laser ablation and cutting allow the precise shaping of ceramics.

- CO2 and Nd: YAG lasers are commonly used for intricate designs.

- Electrochemical Machining (ECM):

- ECM selectively removes material using electrolytes and controlled current.

- Ideal for complex geometries and fragile ceramics.

Glass in On-Demand Manufacturing

Glass, an amorphous material, combines transparency with strength. From architectural windows to optical lenses, glass fabrication demands precision.

Key techniques include:

- Float Glass Process:

- Molten glass floats on a bath of molten tin, resulting in flat, distortion-free sheets.

- Cutting, grinding, and polishing transform float glass into usable forms.

- Chemical Strengthening:

- Ion exchange processes create a compressive layer on the glass surface.

- Gorilla Glass and other strengthened glasses enhance durability.

- Precision Grinding and Edging:

- CNC-controlled machines grind and shape glass to micron-level accuracy.

- Edging ensures smooth, safe edges for glass components.

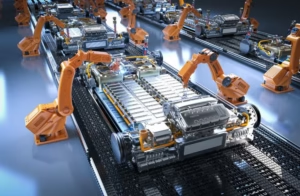

Mechkonnect: Your On-Demand Manufacturing Partner

Mechkonnect shares the commitment to excellence. Our expertise in precision fabrication extends to ceramics and glass. We tailor fabrication processes to your specific needs. Whether it’s a delicate glass lens or a high-strength ceramic component, we deliver. Our state-of-the-art facilities house advanced CNC machines, laser systems, and sintering furnaces. Quality and precision are non-negotiable. We engage with clients across industries, ensuring seamless communication. Your vision becomes our mission.

Contact Mechkonnect today to explore how we can elevate your manufacturing endeavours.