AI Integration in On-Demand Manufacturing: Enhancing Efficiency and Precision

The landscape of manufacturing is rapidly evolving, driven by technological advancements. One such transformative force is Artificial Intelligence (AI). In the context of on-demand manufacturing, AI plays a pivotal role in optimizing processes, improving quality, and meeting customer demands.

In this article, we delve into the ways AI is revolutionizing the manufacturing sector and explore its impact on on-demand production

The Rise of On-Demand Manufacturing

On-demand manufacturing refers to the production of goods based on real-time demand rather than traditional mass production. It aligns perfectly with the principles of lean manufacturing, where waste reduction and flexibility are paramount. As consumer expectations evolve, businesses are turning to on-demand models to stay competitive

How AI Fits In

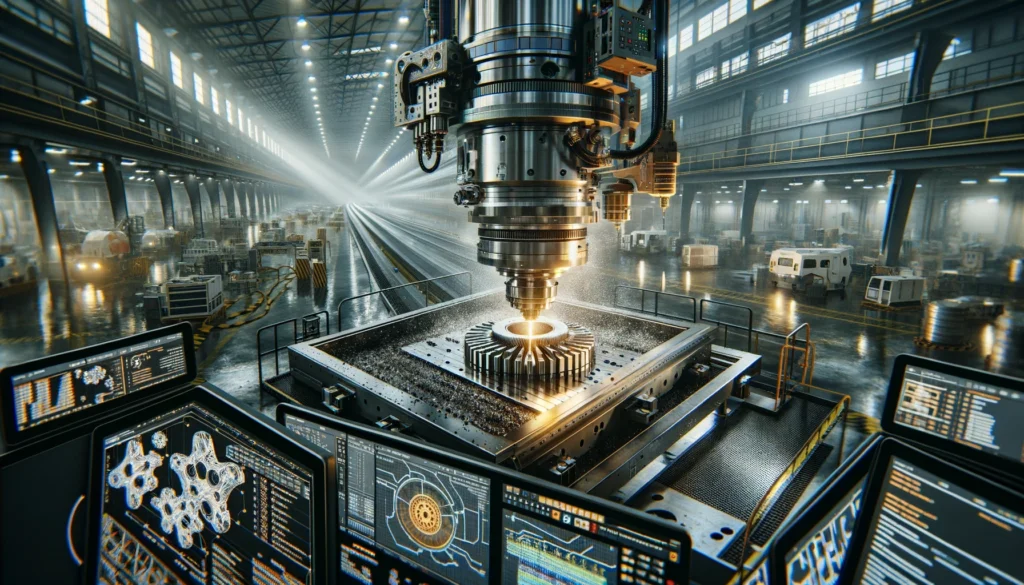

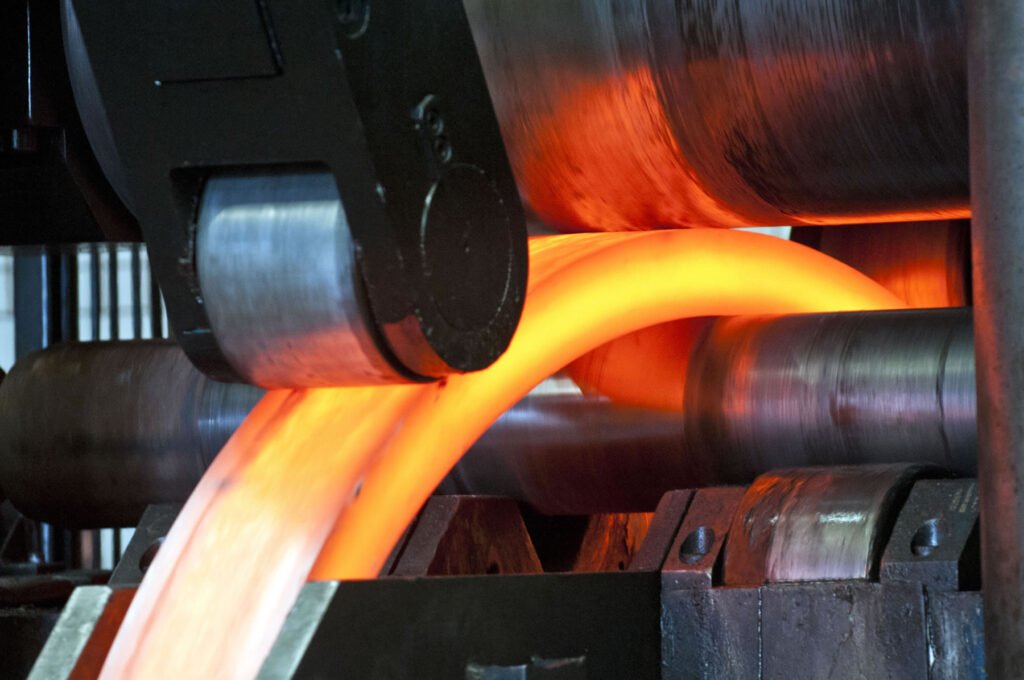

- Predictive Maintenance

AI-driven predictive maintenance ensures that machinery and equipment remain operational without unexpected downtime. By analyzing historical data, sensor readings, and performance metrics, AI algorithms can predict when maintenance is needed. This proactive approach minimizes disruptions and maximizes production uptime.

- Quality Control

Quality control is critical in manufacturing. AI-powered visual inspection systems can detect defects, inconsistencies, and deviations from specifications. Cameras and sensors capture real-time images of products, and machine learning algorithms identify anomalies. Whether it’s identifying faulty components or ensuring precise measurements, AI enhances quality assurance.

- Supply Chain Optimization

On-demand manufacturing relies on efficient supply chains. AI optimizes inventory management, demand forecasting, and supplier selection. Algorithms analyze historical data, market trends, and external factors to predict demand fluctuations. This enables manufacturers to maintain optimal stock levels and reduce excess inventory costs.

- Customization and Personalization

Consumers increasingly seek personalized products. Customised products can be tailored to individual needs with AI. From custom-made shoes to personalized electronics, manufacturers can leverage AI to create unique offerings efficiently.

- Production Scheduling

Balancing production schedules is complex. AI algorithms consider factors like machine availability, lead times, and order priorities. They create optimized schedules that minimize idle time and maximize resource utilization.

- Energy Efficiency

Manufacturing consumes significant energy. AI-driven energy management systems monitor usage patterns, identify inefficiencies, and suggest energy-saving measures. Whether it’s adjusting equipment settings or optimizing lighting, AI contributes to sustainability.

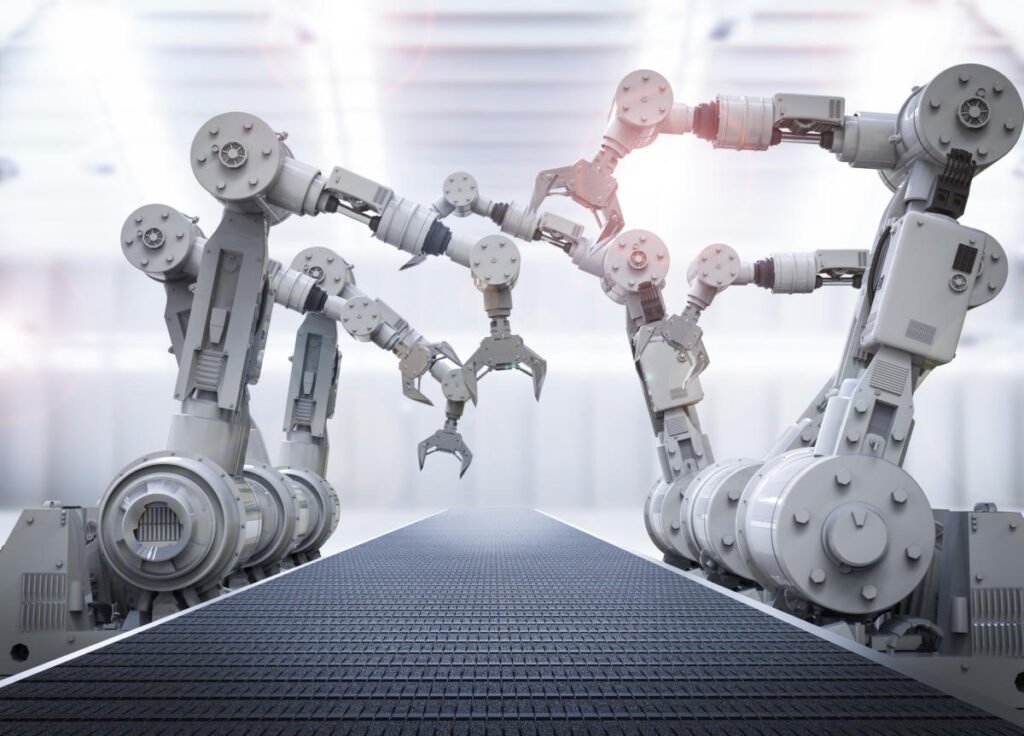

- Collaborative Robots (Cobots)

Cobots work alongside human operators, enhancing productivity and safety. AI enables cobots to adapt to changing tasks, learn from human interactions, and perform repetitive actions. They handle intricate assembly tasks, reducing human error and fatigue.

Challenges and Considerations

While AI offers immense benefits, its implementation requires careful planning:

Data Quality: Reliable AI models depend on high-quality data. Manufacturers must ensure accurate data collection and cleansing.

Ethical Use: AI decisions impact people’s lives. Transparency, fair-mindedness, and ethical considerations are crucial.

Skill Gap: Manufacturers need skilled personnel to develop, deploy, and maintain AI systems.

AI integration in on-demand manufacturing is not a distant future—it’s happening now. As businesses embrace AI, they gain agility, efficiency, and competitive advantage. The synergy between human expertise and AI capabilities will shape the future of manufacturing, making it smarter, faster, and more responsive to customer needs.

Ready to Revolutionize Your Manufacturing?

Mechkonnect’s integration of AI in on-demand manufacturing is not a distant vision—it’s a reality. As Mechkonnect embraces AI, agility, efficiency, and competitive advantage follow suit. The synergy between human expertise and AI capabilities will shape the future of manufacturing, making it smarter, faster, and more responsive to customer needs.

Our commitment to excellence drives us to embrace cutting-edge technologies like AI integration in on-demand manufacturing. Are you ready to:

- Streamline your production processes, reduce downtime, and maximize resource utilization.

- From defect detection to precision measurements, our AI ensures top-notch quality control.

- On-demand manufacturing demands flexibility. With AI, we adapt to real-time demand fluctuations.

- Say goodbye to excess stock and stockouts. Our AI-driven inventory management keeps your supply chain finely tuned.

- Timely fulfillment is our promise. AI helps us meet customer demands promptly.

Join the Mechkonnect revolution. Let’s shape the future of manufacturing together! Contact us today at info@mechkonnect.com or visit our website at www.mechkonnect.com.

Recent Post