A Beginner’s Guide to Understanding Various 3D Printing Techniques

3D printing, also known as additive manufacturing, has transformed multiple industries by providing the ability to produce intricate objects layer by layer from digital designs. Its undeniable impact has opened up new possibilities for innovation and creativity.

Are you curious about the latest 3D printing technologies? Let’s dive into the fascinating world of 3D printing and explore the various types of 3D printing techniques that are being used today. From Fused Deposition Modeling (FDM) to Stereolithography (SLA), there’s a lot to discover! Join us on this exciting journey of exploring the different types of 3D printing technologies.

- Stereolithography (SLA)

Stereolithography utilizes a vat of liquid photopolymer resin cured by a UV laser to create solid objects layer by layer. The UV laser traces the pattern of the object’s cross-section on the surface of the liquid resin, hardening it. Once a layer is complete, the build platform moves downward, and the process repeats until the entire object is formed. SLA is renowned for its high precision and surface finish, making it suitable for producing prototypes, intricate models, and dental applications.

Example: Prototyping of intricate mechanical parts.

- Selective Laser Sintering (SLS)

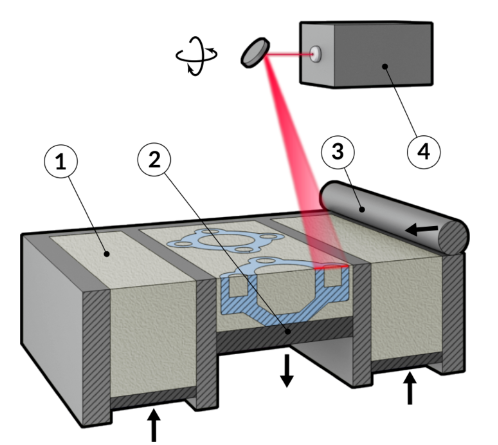

Selective Laser Sintering employs a high-powered laser to selectively fuse powdered material, typically nylon or metal, into a solid structure layer by layer. The laser sinters the powdered material based on a digital 3D model, allowing for the creation of complex geometries without the need for support structures. SLS is widely used in automotive, aerospace, and medical industries for producing functional prototypes, end-use parts, and tooling components.

Example: Manufacturing custom prosthetics and aerospace components.

- Fused Deposition Modeling (FDM)

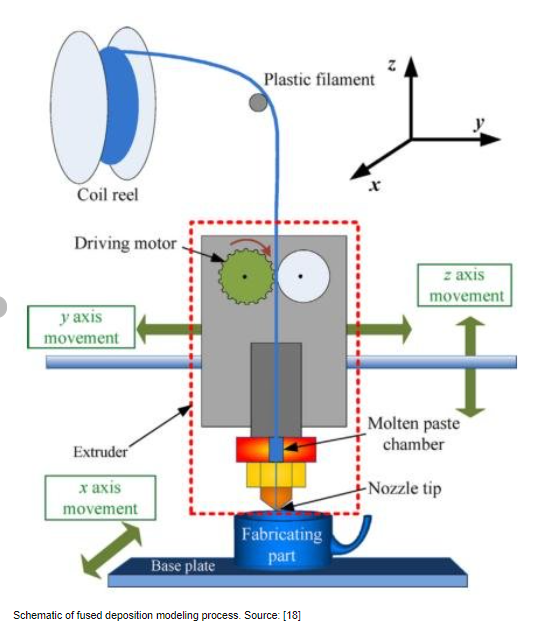

Fused Deposition Modeling is one of the most common 3D printing technologies, where a thermoplastic filament is heated and extruded through a nozzle onto a build platform layer by layer. The material solidifies as it cools, forming the desired object. FDM is known for its affordability, simplicity, and versatility, making it suitable for rapid prototyping, architectural models, and educational purposes.

Example: Creating functional prototypes and educational models.

- Digital Light Processing (DLP)

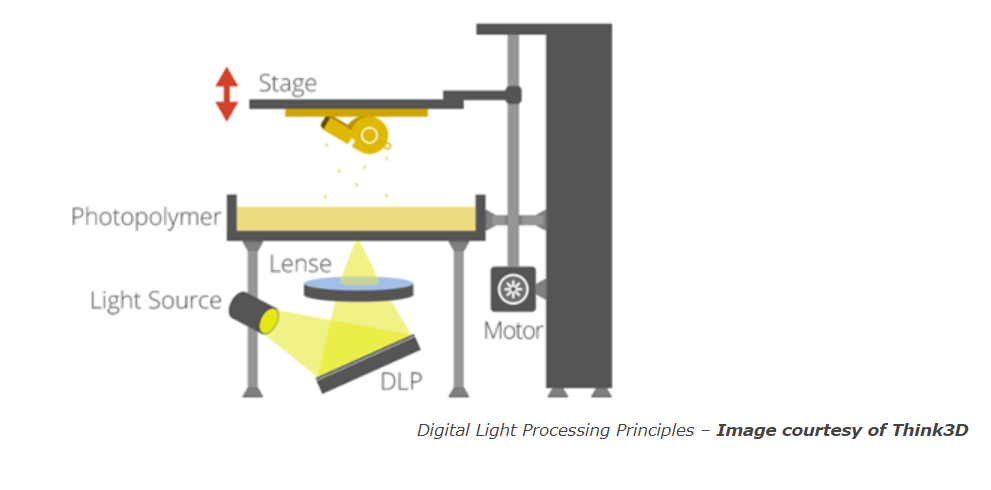

Digital Light Processing utilizes a digital light projector to cure liquid photopolymer resin layer by layer. Similar to SLA, DLP also employs photopolymerization to solidify the resin, but instead of a laser, it uses a light projector to cure entire layers simultaneously. DLP offers faster print speeds compared to SLA, making it ideal for producing dental appliances, jewelry, and consumer products with intricate details.

Example: Crafting jewelry designs and dental crowns.

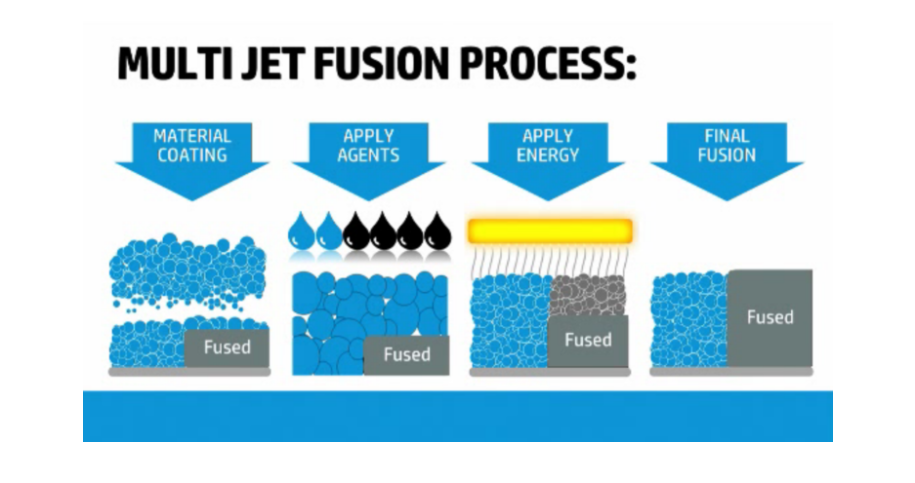

- Multi Jet Fusion (MJF)

Multi Jet Fusion is an advanced 3D printing technology developed by HP that utilizes inkjet arrays to selectively apply fusing and detailing agents onto a bed of powdered material. Subsequently, thermal energy is applied to fuse the powder, resulting in high-resolution parts with excellent mechanical properties. MJF is suitable for producing functional prototypes, end-use parts, and custom manufacturing components.

Example: Manufacturing lightweight and durable automotive parts.

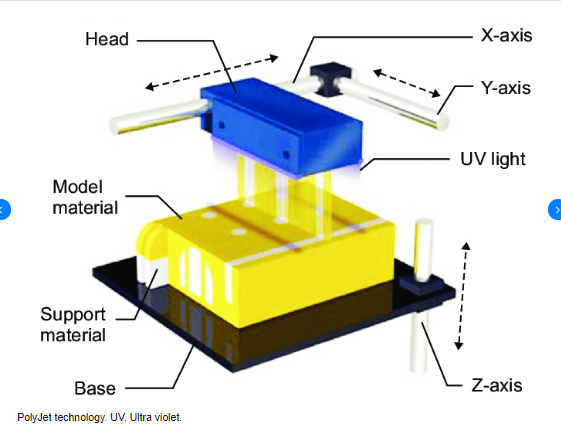

- PolyJet

PolyJet technology employs inkjet-like printheads to jet layers of liquid photopolymer onto a build platform. The layers are cured instantly using UV light, allowing for the creation of parts with varying material properties and colors within a single print. PolyJet is utilized in industries such as consumer goods, medical, and aerospace for producing detailed prototypes, architectural models, and medical devices.

Example: Creating realistic medical prototypes and architectural models.

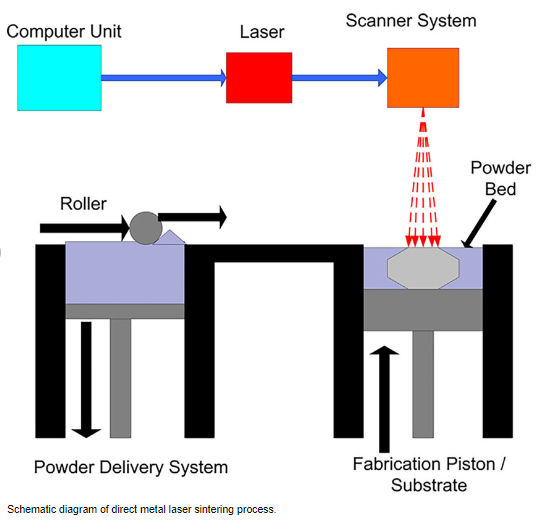

- Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering utilizes a high-powered laser to fuse metal powder into solid parts layer by layer selectively. DMLS enables the production of complex geometries and functional metal components with high strength and precision. This technology finds applications in aerospace, automotive, and medical industries for manufacturing parts with intricate designs and superior mechanical properties.

Example: Fabricating aerospace components and medical implants.

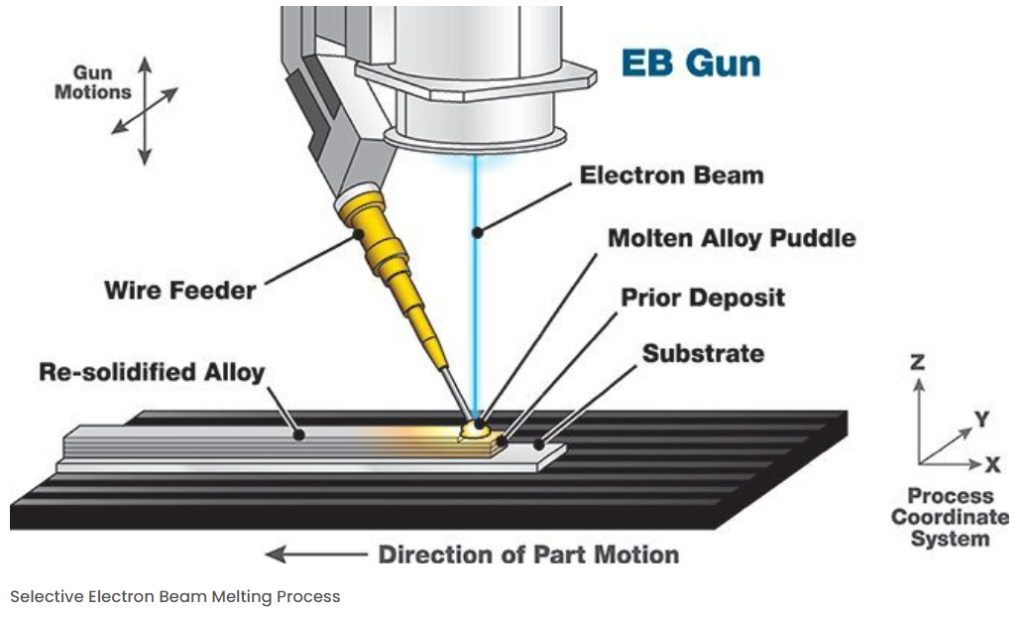

- Electron Beam Melting (EBM)

Electron Beam Melting employs an electron beam to melt and fuse metal powder in a vacuum environment. EBM offers high build speeds and can produce parts with excellent mechanical properties, making it suitable for aerospace, medical, and automotive applications where strength and precision are crucial.

Example: Manufacturing complex aerospace structures and orthopedic implants.

To simplify, let us understand the types of 3D printing through a comparison table.

3D Printing Technology Comparison Table

Technology | Process | Applications | Example |

SLA- Stereolithography | UV laser cures the resin | Prototyping, dental, and intricate models | Prototyping of mechanical parts |

SLS- Selective Laser Sintering | Laser sinters powder | Automotive, aerospace, medical | Custom prosthetics |

FDM- Fused Deposition Modeling | Extrudes thermoplastic | Prototyping, educational models, architectural models | Functional prototypes |

DLP- Digital Light Processing | Light projector cures resin | Jewelry, dental, and consumer products | Jewelry designs |

MJF- Multi Jet Fusion | Inkjet applies agents | Functional prototypes, end-use parts, manufacturing | Lightweight automotive parts |

PolyJet Technology | Inkjet jets photopolymer | Consumer goods, medical, aerospace | Realistic medical prototypes |

DMLS- Direct Metal Laser Sintering | Laser sinters metal | Aerospace, automotive, medical | Aerospace components |

EBM- Electron Beam Melting | Electron beam melt metal | Aerospace, medical, automotive | Orthopedic implants |

Mechkonnect can Support Providing 3D Printing Solutions

Mechkonnect specializes in providing comprehensive 3D printing solutions tailored to meet the unique needs of various industries. With a team of experienced engineers and state-of-the-art technology, Mechkonnect offers a wide range of services, including prototype development, rapid manufacturing, and customized part production. Whether you require high-precision prototypes for testing or functional end-use parts for production, Mechkonnect’s expertise in 3D printing technologies ensures quality, efficiency, and cost-effectiveness.

Recent Post